Electric Powered, Near Infrared Radiation Coffee Roasters

Rubasse Micro

3kg Fully-Automated Production Workhorse

Fully automated bean charging, roasting, cooling, and releasing.

Exclusive near-infrared technology for powerful, responsive, and easy operation.

Exclusive near-infrared technology for powerful, responsive, and easy operation.

Rubasse Hyper

1.2kg Table-top Coffee Roasting Powerhouse

A Small & Compact 1kg Coffee Roaster; The Perfect Match for Small-Scale Production

Rubasse Nano

600g Plug-and-Play Compact Coffee Roaster

Professional roasting experience packed into a home-friendly footprint

“Heat Resonator” Roast Chamber Design

The Most Energy Efficient Roasting System Available

The radiant energy inside the roast chamber would:

By “resonating” radiant heat energy within the roast chamber, Rubasse roasters achieved unprecedented energy efficiency.

Automated Workflow

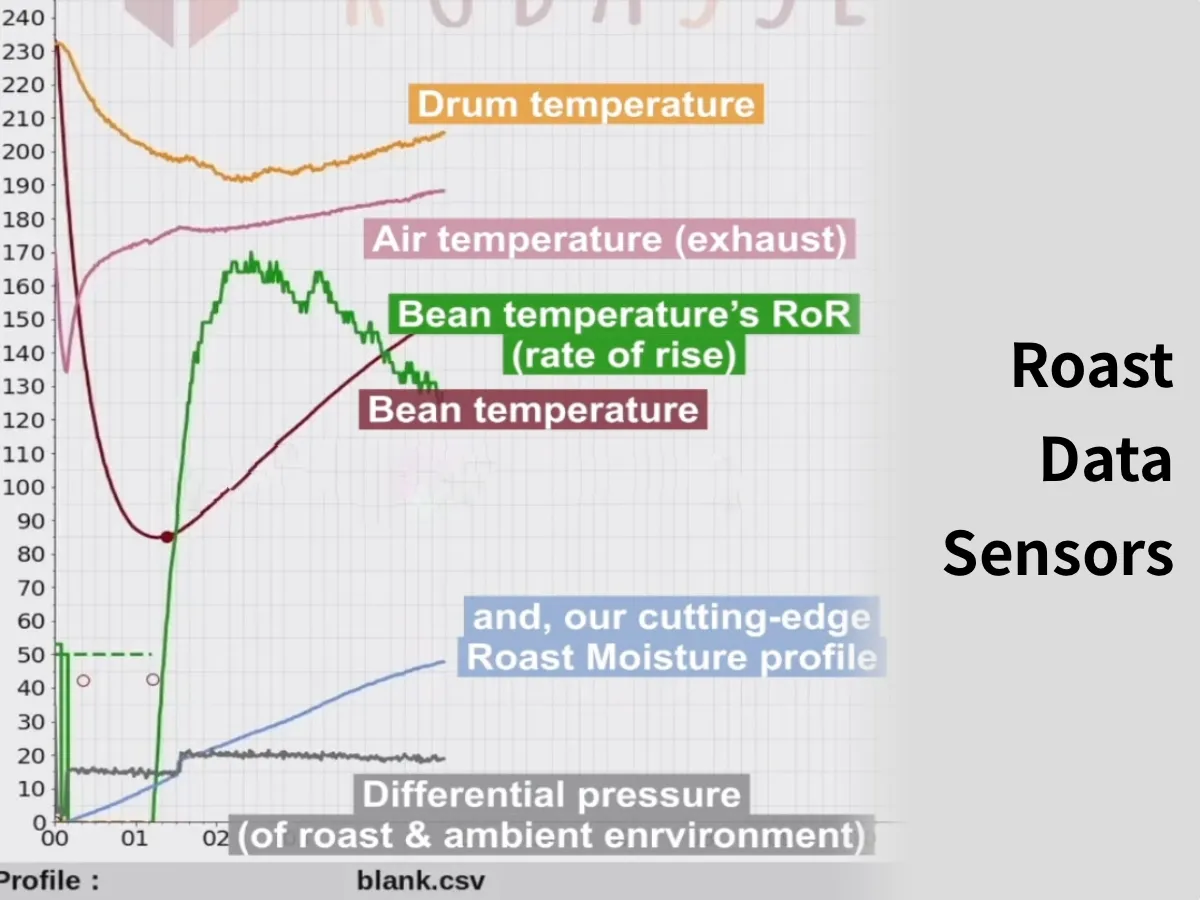

Digital Roast Data Collection

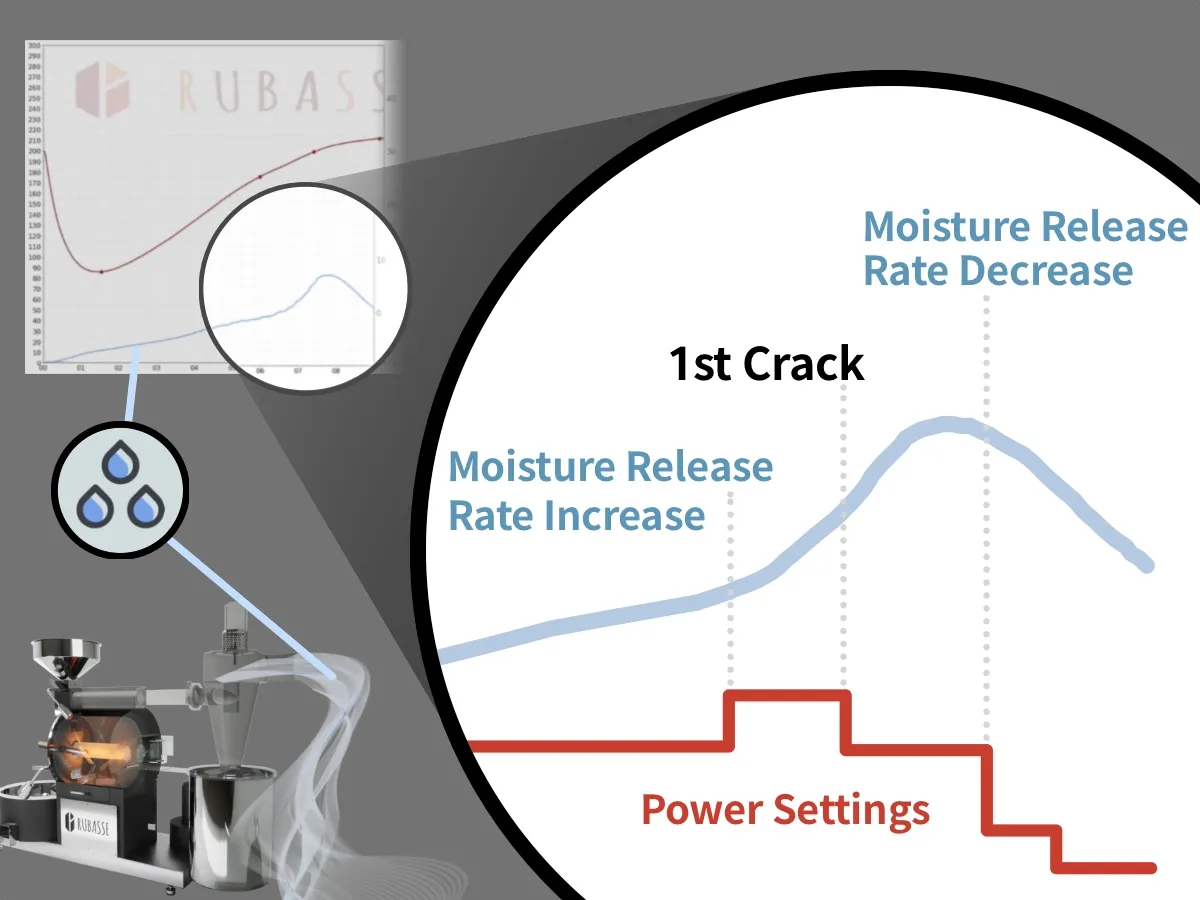

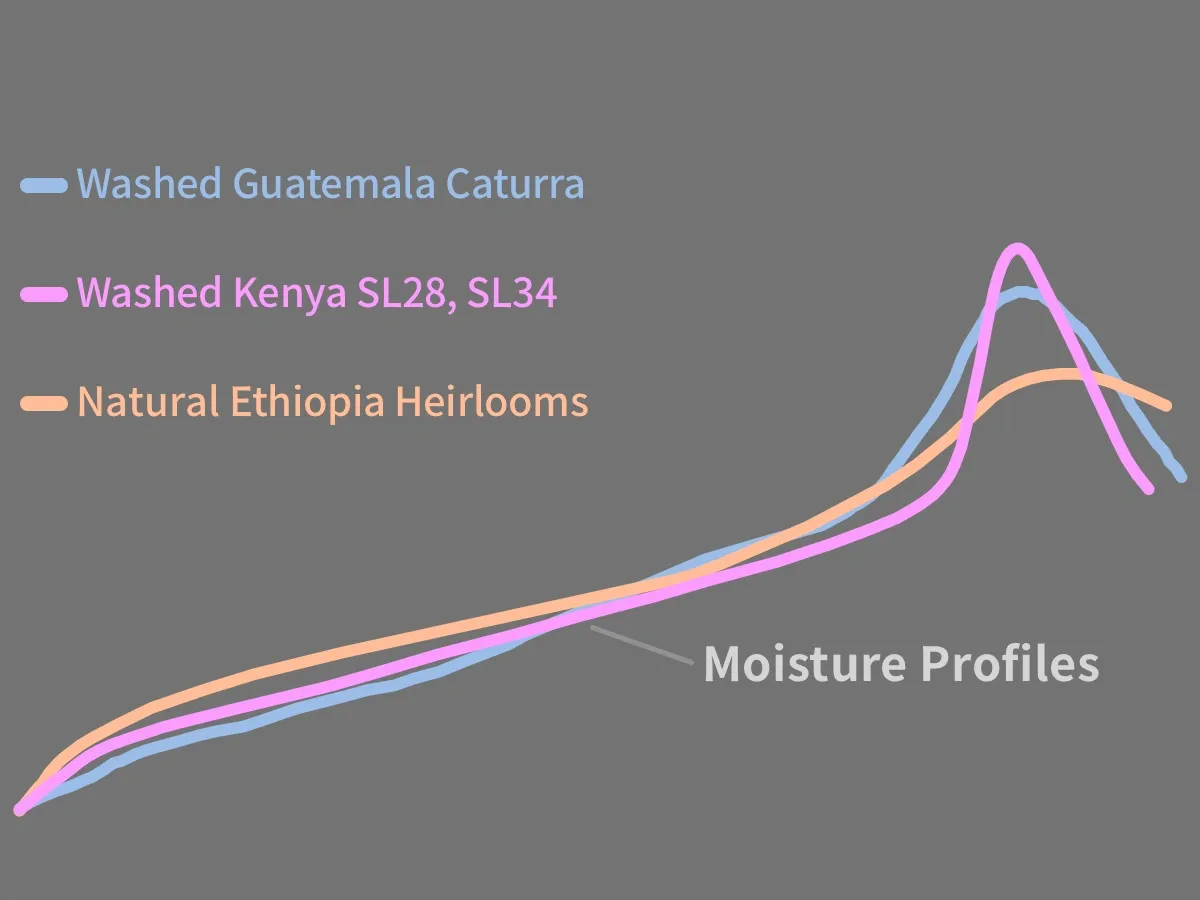

Roast Moisture

Digital Roast Data Collection

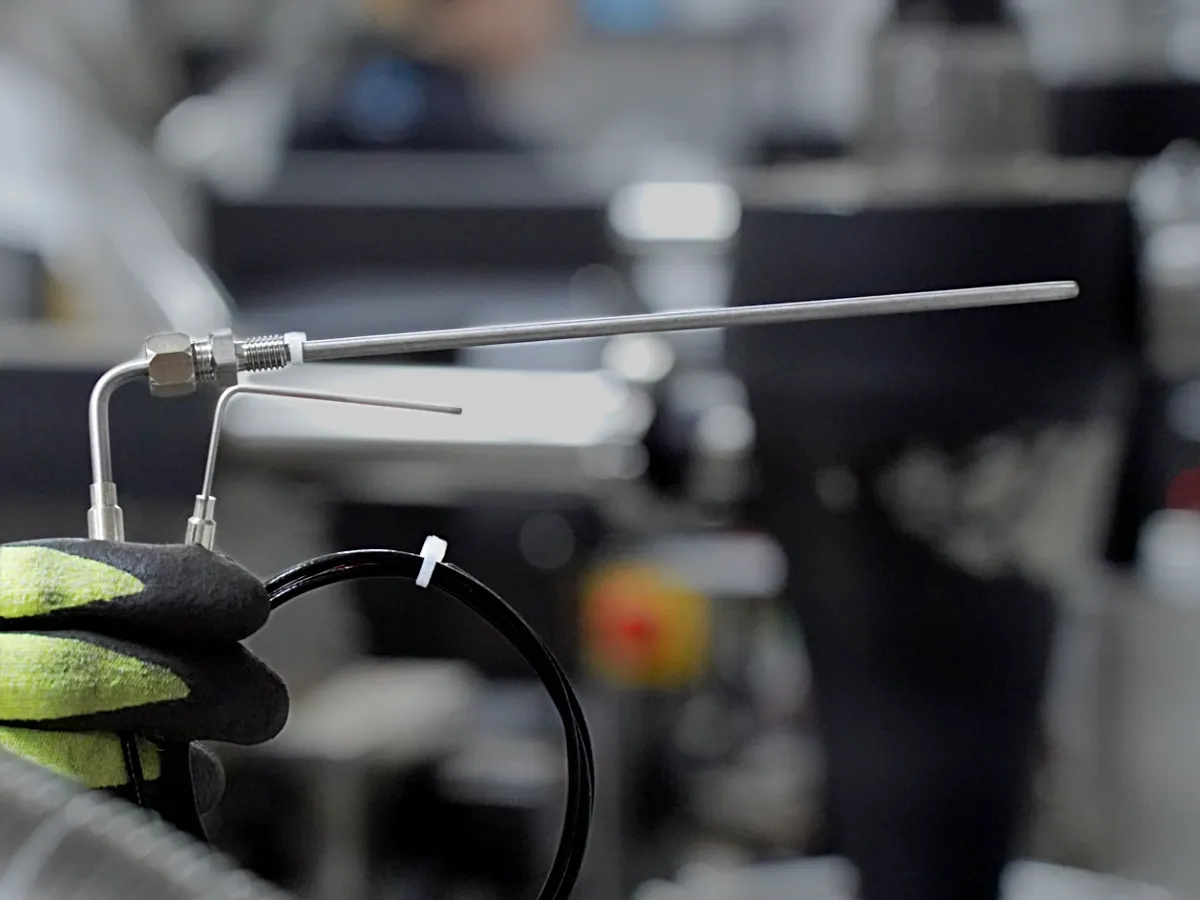

Data Sensors

600+ coffee enthusiasts all round the world

Invite you to become Rubasse friend, digging out the coffee roasting together!

Find Your Nearest Distributor

… or become one in your region!