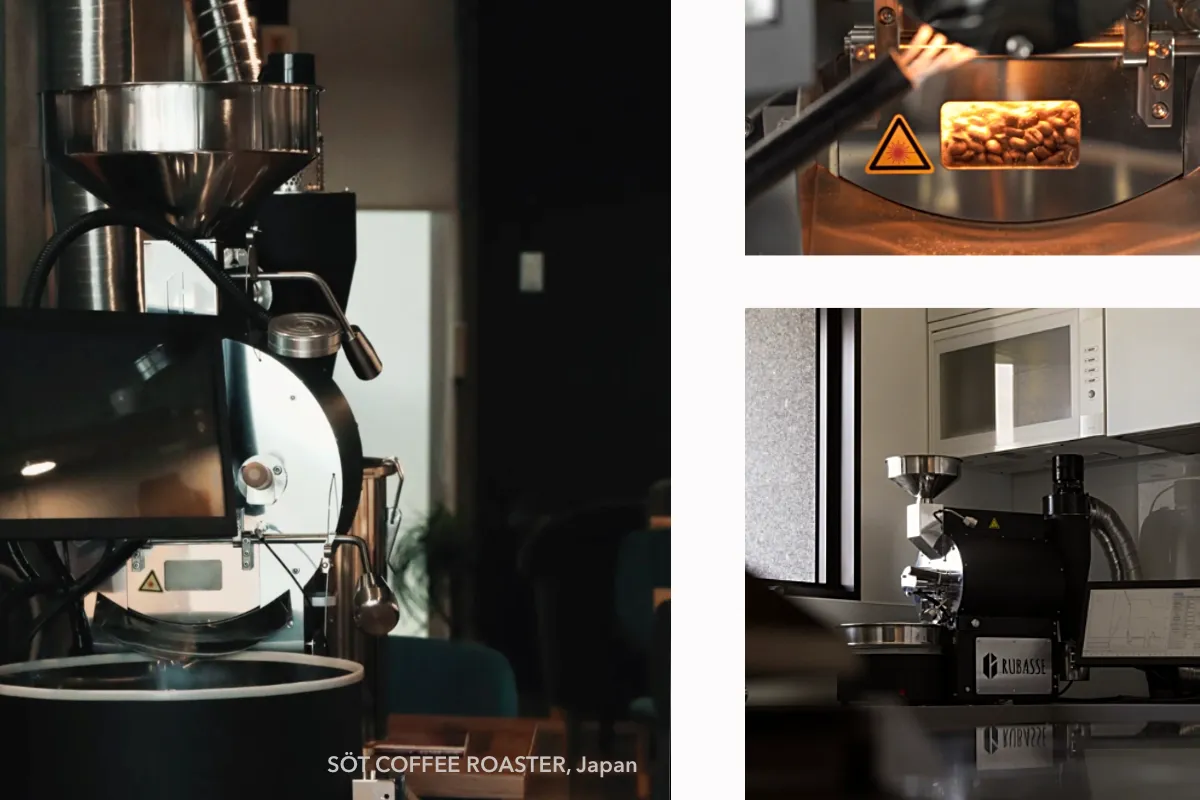

Smarter & Better Coffee Roasting

Radiation Roasting

Easier roast development, 50% less energy usage, and better for the environment — Near Infrared Radiation makes them all possible.

Radiation redesigns roasting in a truly innovative fashion.

Radiation redesigns roasting in a truly innovative fashion.

One Touch, Smart Replication

Full-auto roasting process & precise roast profile replication ensures efficient and care-free production.

Minimal work, optimal results — time after time.

Minimal work, optimal results — time after time.

Live Roast Moisture Data

Introducing new roast data that deepens our understanding about coffee roasting — Starting with the world’s first roast moisture detection function.

Learn the details of each green coffees and control your roasts with precision like never before.

Learn the details of each green coffees and control your roasts with precision like never before.

Cutting-edge technology for roasting better coffee in a smarter & more efficient way.

Get a Quotation

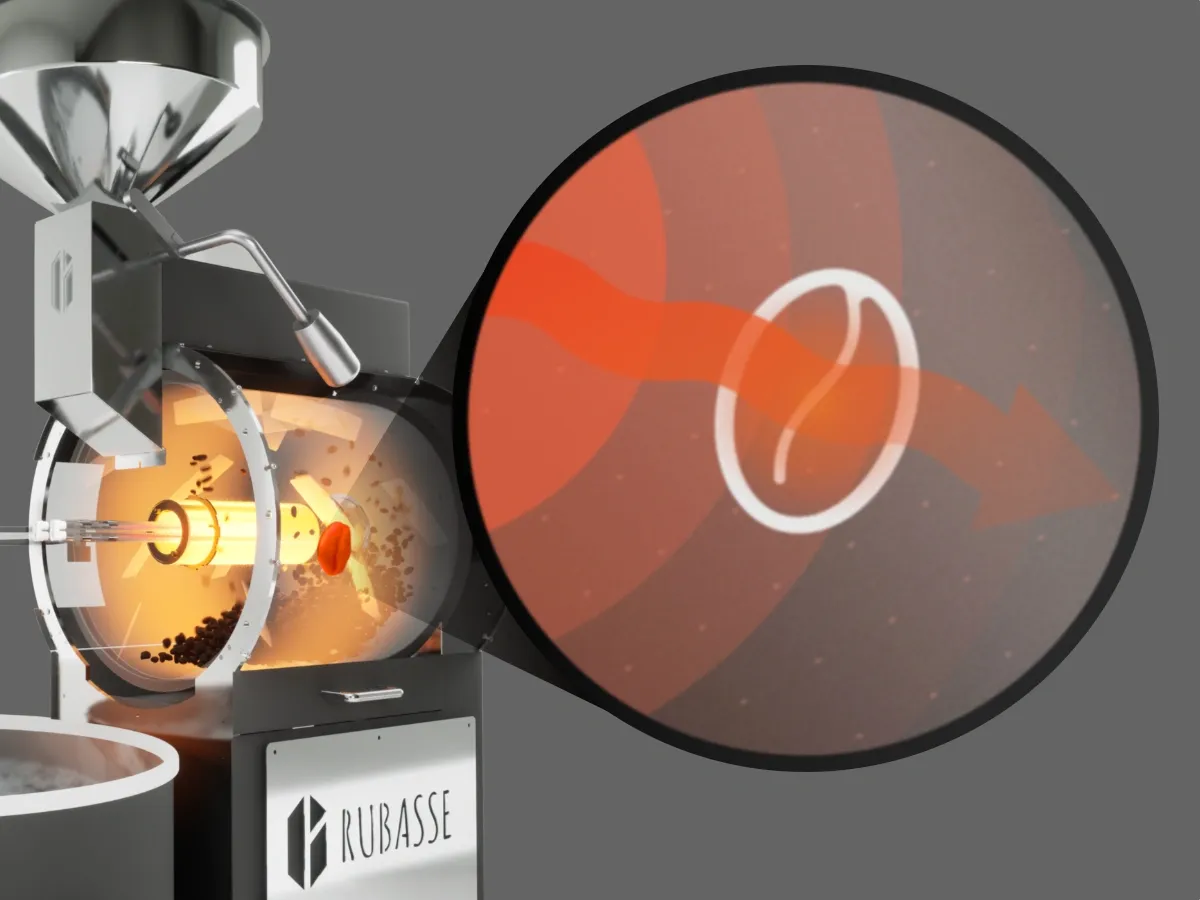

1. Why Roast with NIR Radiation?

Direct Roasting

Using radiation to roast coffee saves you time, energy, and worries about underdeveloping your coffees.

Directly applying penetrative radiant energy onto the beans, radiant heat develops the coffee quicker & more evenly comparing to traditional (convective + conductive) roasting.

Directly applying penetrative radiant energy onto the beans, radiant heat develops the coffee quicker & more evenly comparing to traditional (convective + conductive) roasting.

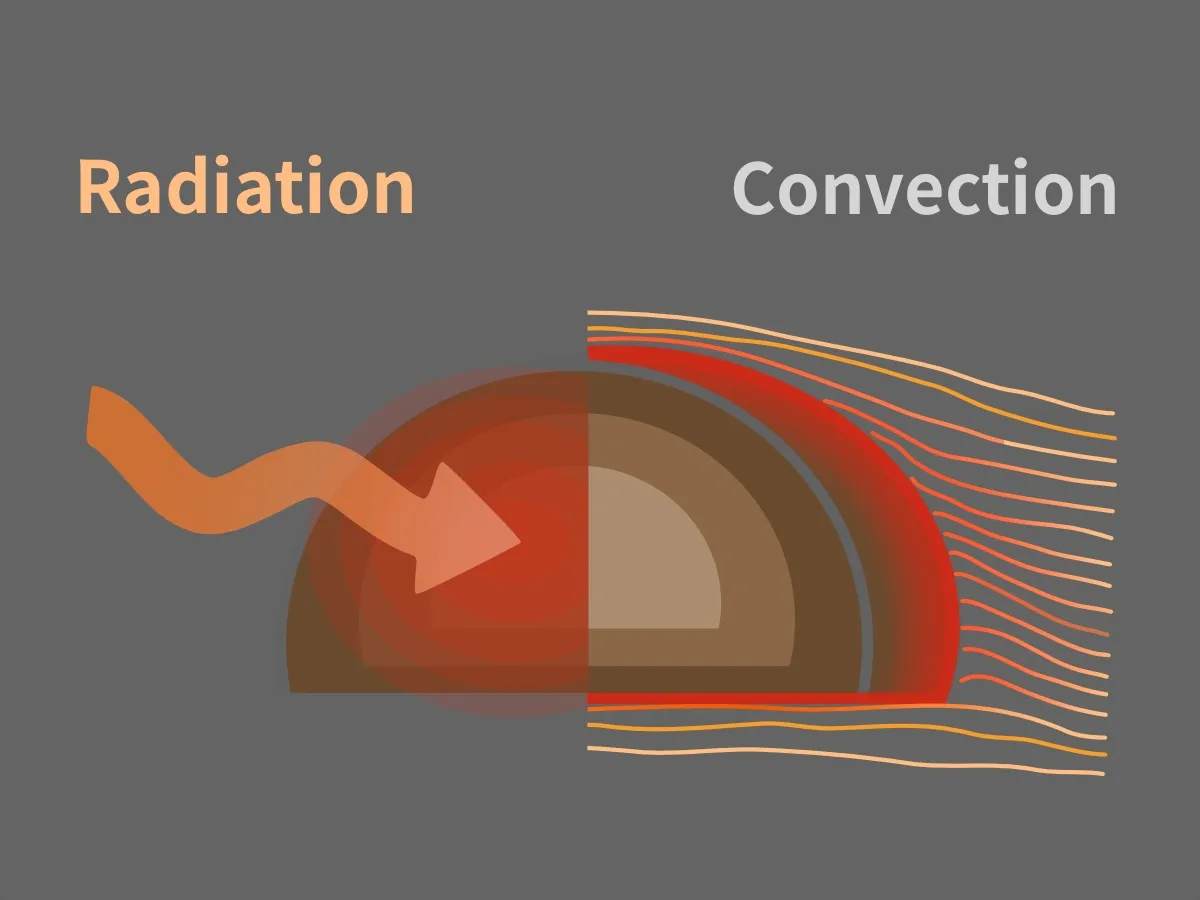

Radiation ≫ Convection

Radiant heat is evenly absorbed by the total mass of a coffee bean.

Convective heat (hot air) is mainly & firstly absorbed by the outer surface of a coffee bean. The heat needs time to penetrate deeper.

Roasting with radiation means:

● Faster roast development (especially as the beans get darker)

● Less uneven and/or prolonged “baked” roasts.

Convective heat (hot air) is mainly & firstly absorbed by the outer surface of a coffee bean. The heat needs time to penetrate deeper.

Roasting with radiation means:

● Faster roast development (especially as the beans get darker)

● Less uneven and/or prolonged “baked” roasts.

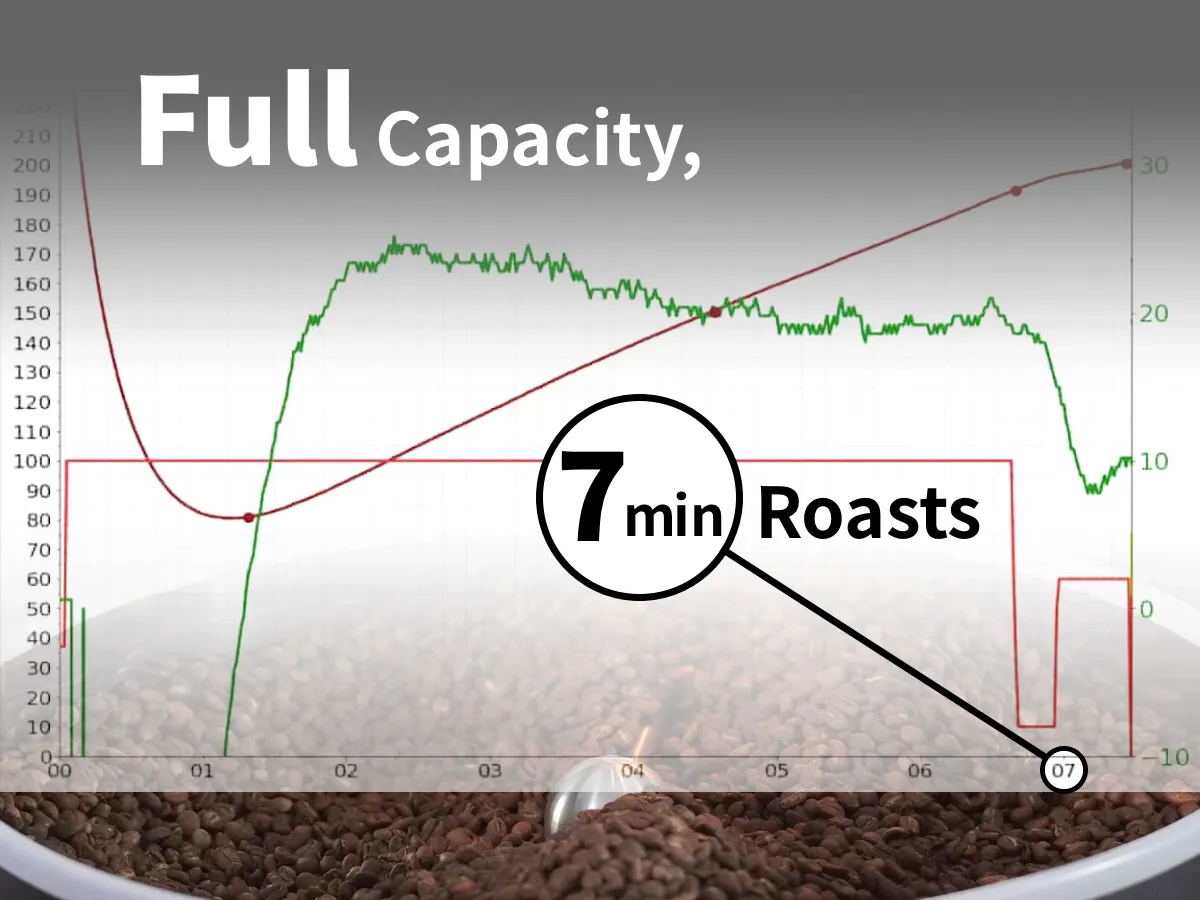

Powerful Roasting

Gone are the days of slow and sluggish electric coffee roasters.

Near Infrared Radiation (NIR) roasting machines can achieve roasting durations similar to (or faster than) gas-burning roasters while only needing less than half of the total energy consumption.

Near Infrared Radiation (NIR) roasting machines can achieve roasting durations similar to (or faster than) gas-burning roasters while only needing less than half of the total energy consumption.

” …This results in approximately 50% less energy consumption due to the effective heat method. “

(page 12, EECA Technology Scan report)

( Link to the full report is at the end of this page )

( Link to the full report is at the end of this page )

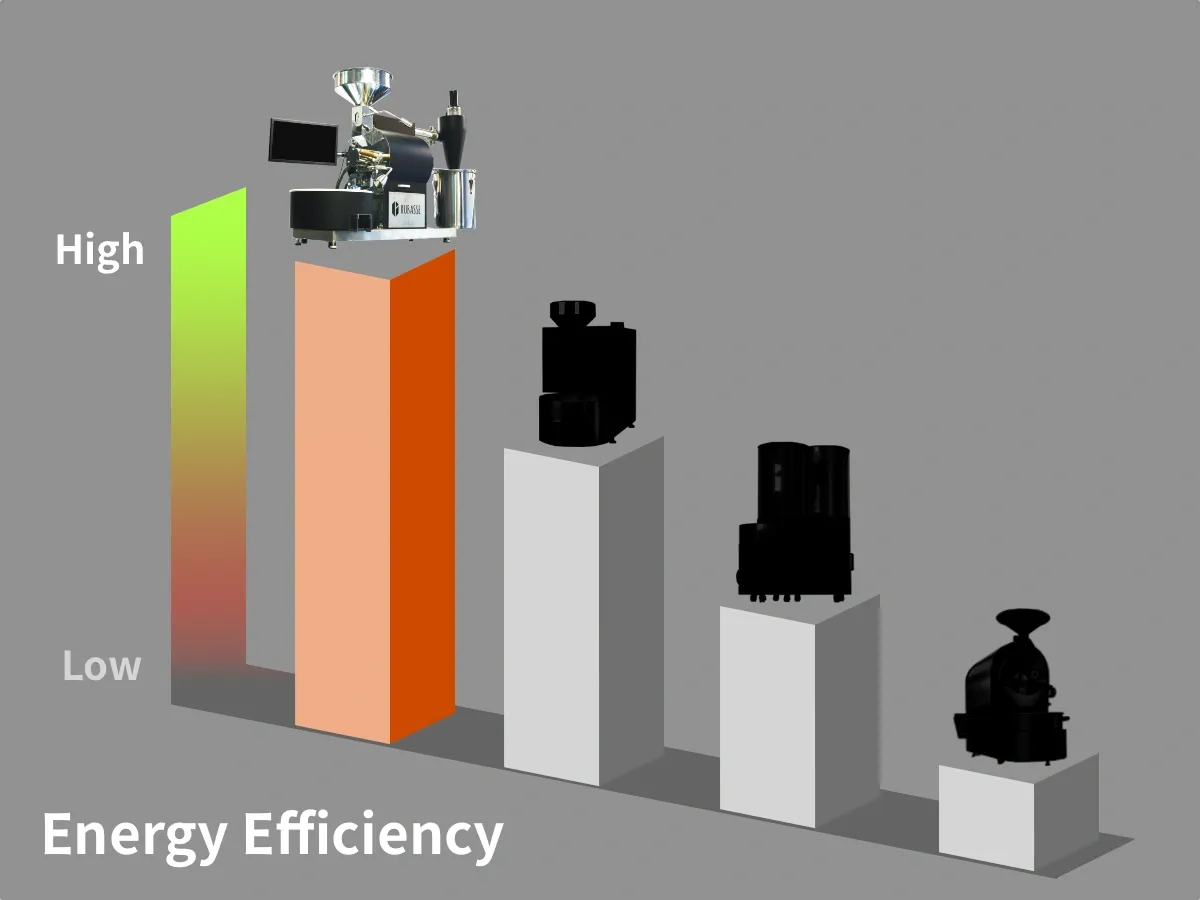

>50% Roast Energy Savings

Switching the primary roasting energy source from hot air to radiation benefits roasters with tremendous energy savings.

Our center-placed radiation power element ensured maximum radiant heat utilization, resulting in the world’s most energy efficient roasting process (proven by the 3rd party research in the Appendix section below).

Our center-placed radiation power element ensured maximum radiant heat utilization, resulting in the world’s most energy efficient roasting process (proven by the 3rd party research in the Appendix section below).

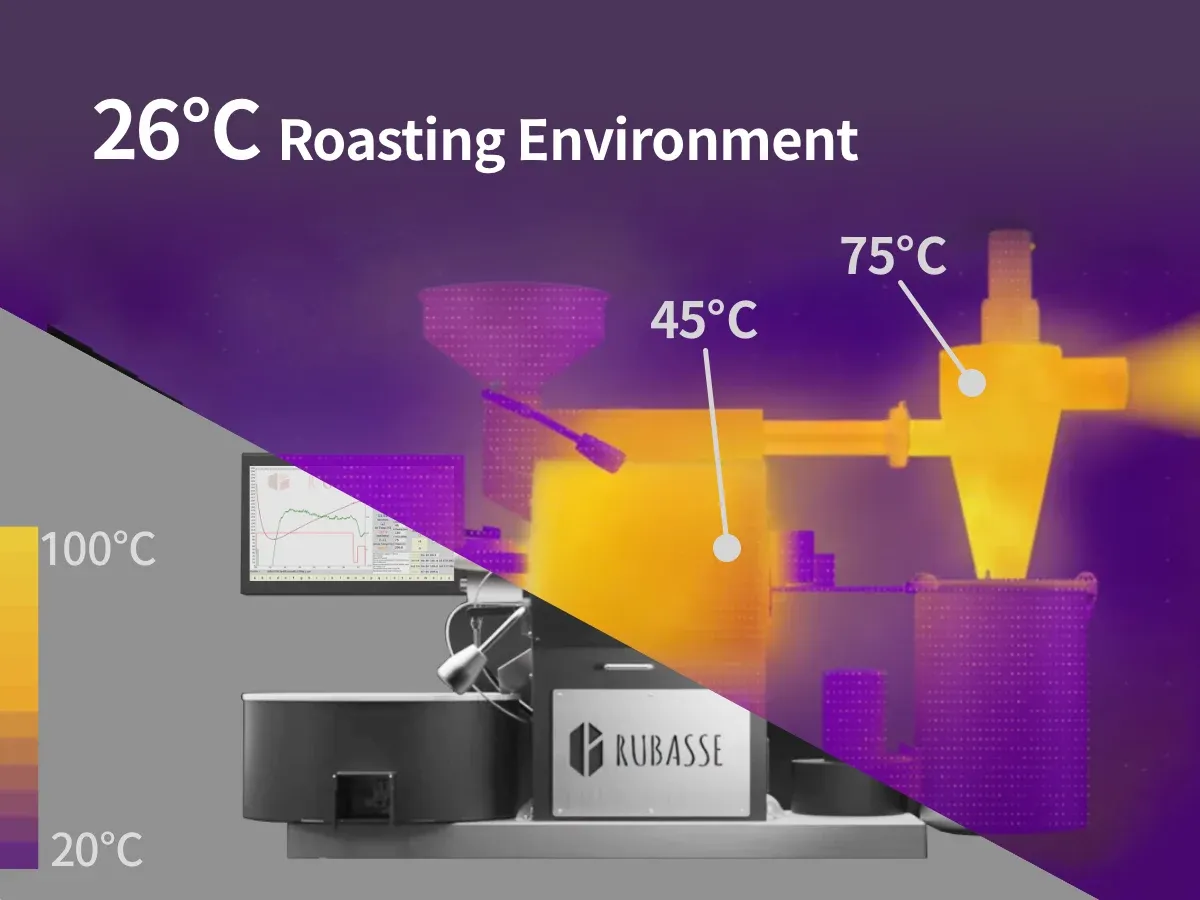

Cool & Comfortable Roasting Environment

Improving roast energy efficiency by roasting with radiation also means less waste heat being released in to the roasting environment.

The benefits:

● Comfortable, cool roasting sessions

● Way less money spent on air conditioning

Experience Radiation Roasting Live

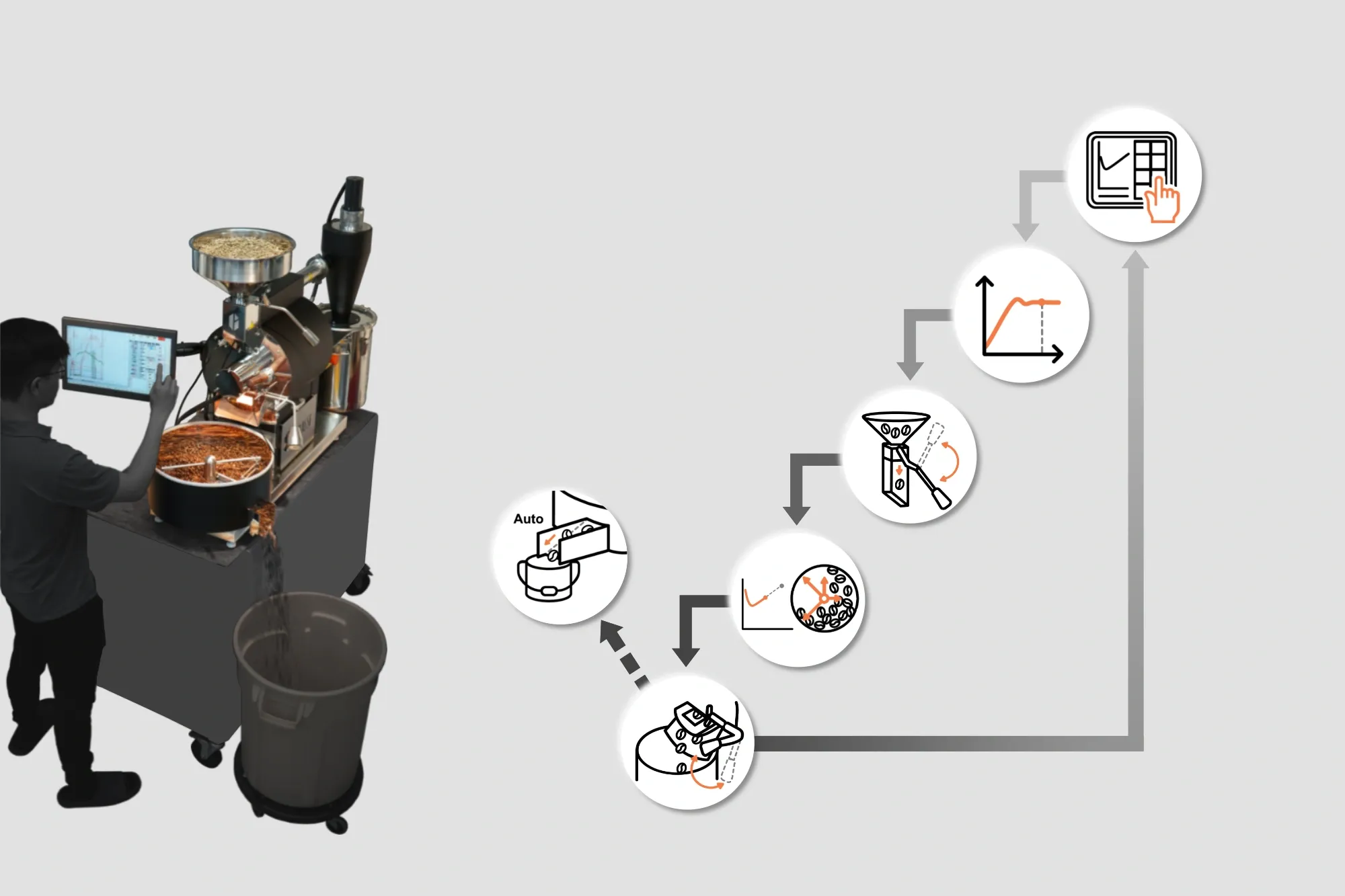

2. Auto Roasting & Profile Replication

One Touch,

Smart Replication

Only 30 seconds of labor per roast

Smart Replication

Only 30 seconds of labor per roast

1. Select saved profile from touch panel

2. Auto preheat & charge temperature idle

3. Auto charging

4. Auto roasting with profile replication

5. Auto discharge & cooling

6. Auto unloading

Auto-Pilot

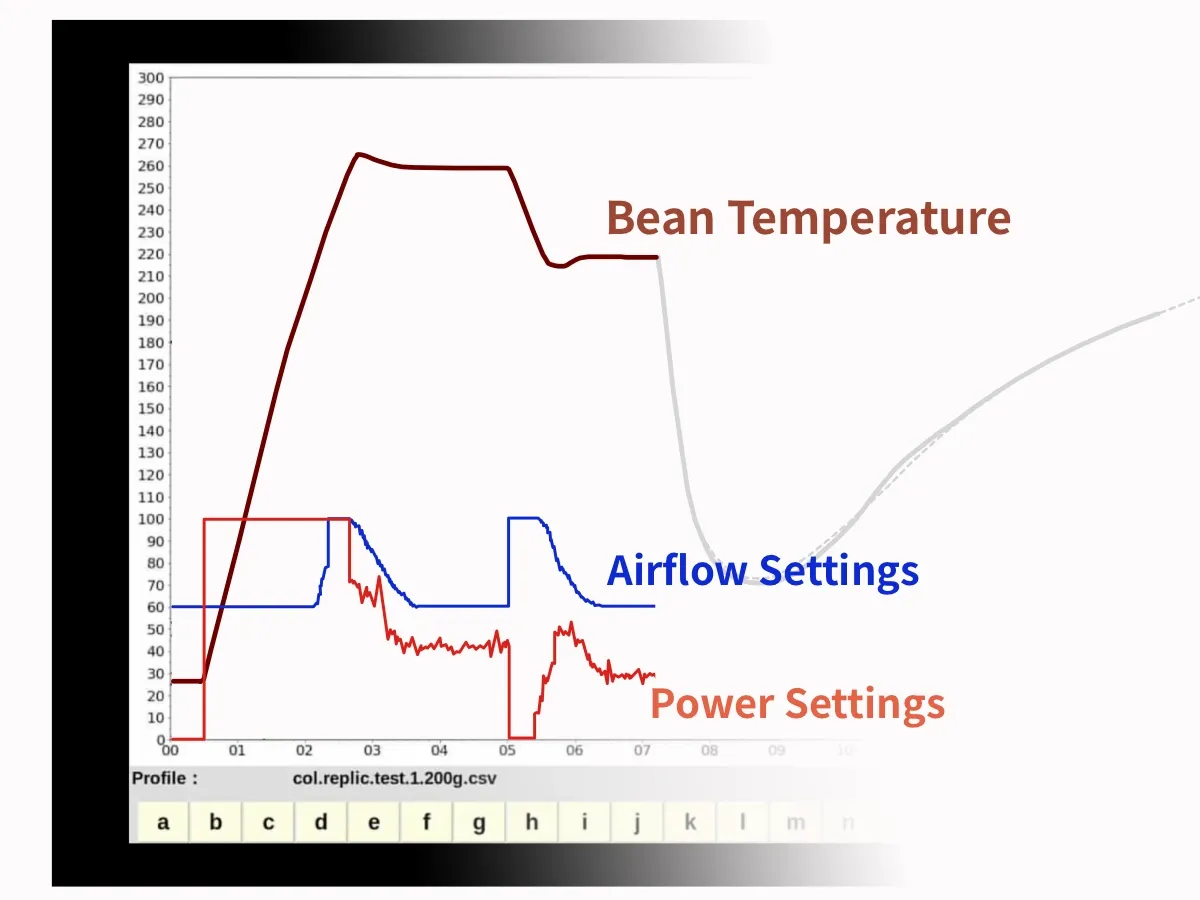

Roast Profile Replication

Smart automation + Precise replication = Minimal work, optimal results

Auto Preheat

The Auto-Pilot system automatically idles the bean temperature at your charge temperature.

Power output and airflow setting are controlled by the system to ensure stable initial energy at the start of the roast.

Auto Roasting

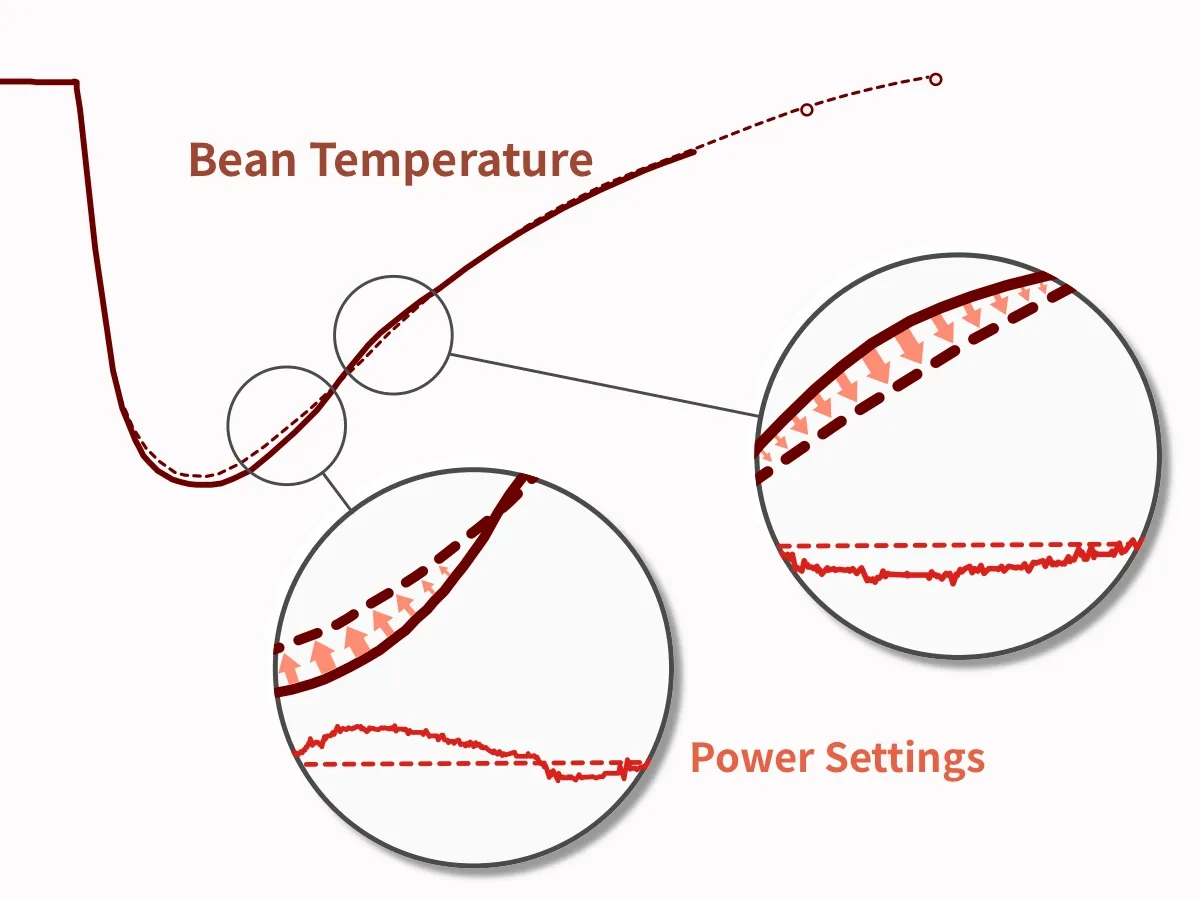

Rubasse Back-tracking Algorithm

Specialized algorithm takes full control over radiation heat & airflow settings, corrects temperature deviations swiftly, and replicates your unique profile with precision both on the graph & in the cup.

Auto Roasting

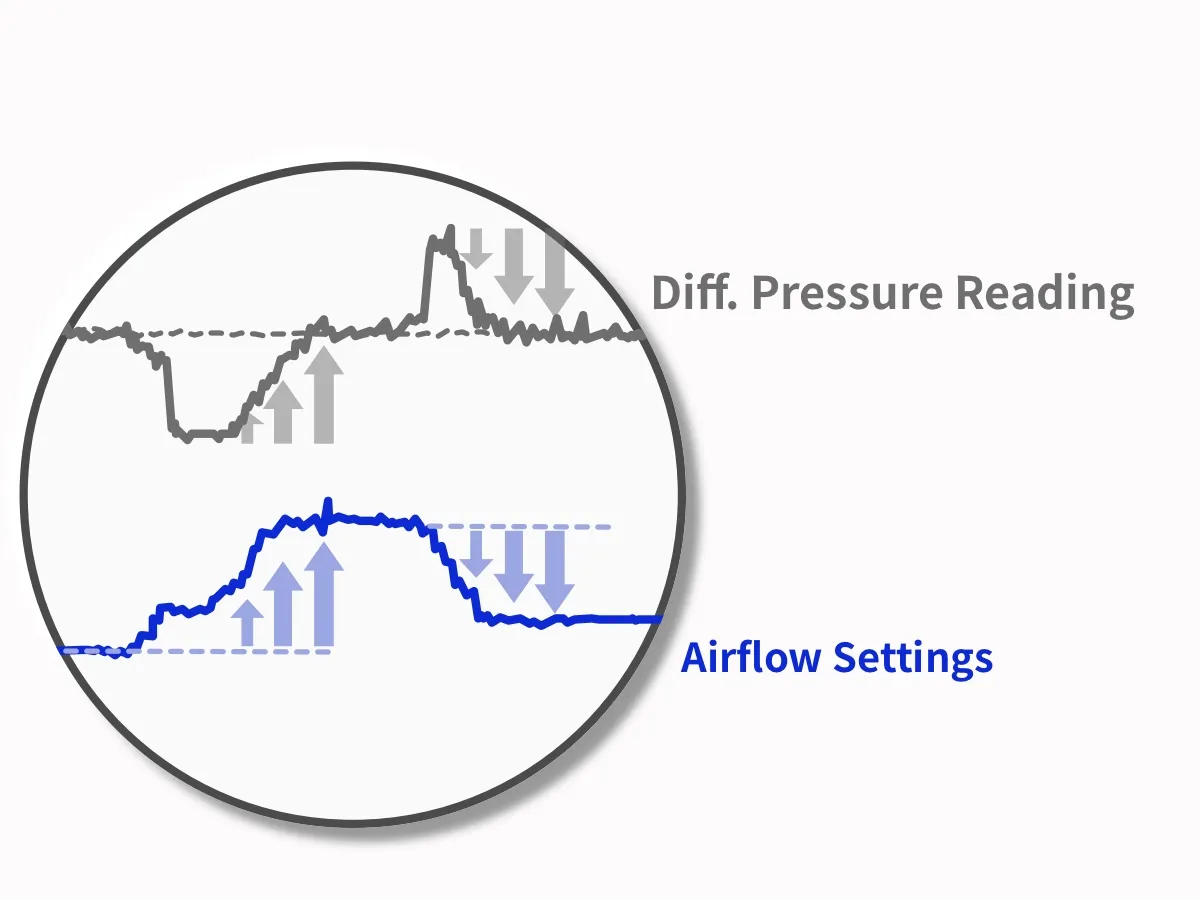

Differential Pressure Profiling

Rubasse’s “Pressure Compensation” feature mitigates possible effects on the roast caused by air pressure issues such as clogged ducts over time or weather/ambient changes…etc.

See the Machine Roast & Replicate

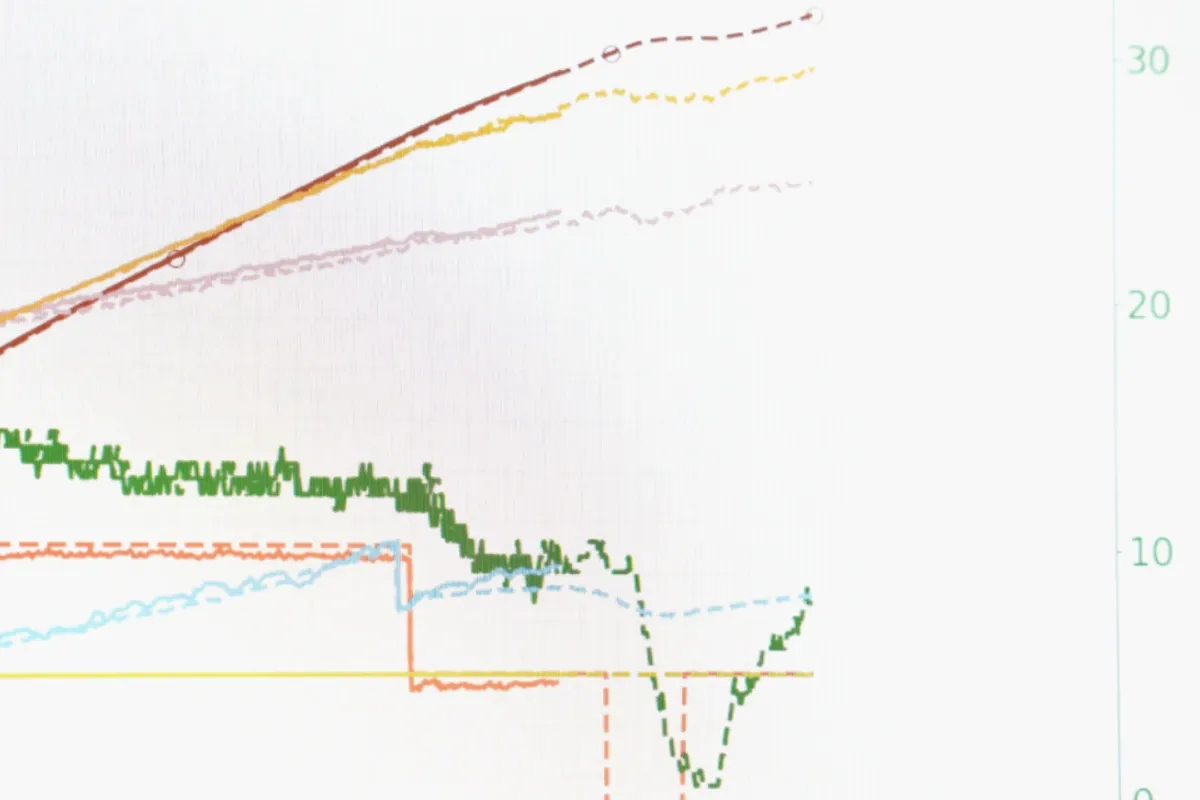

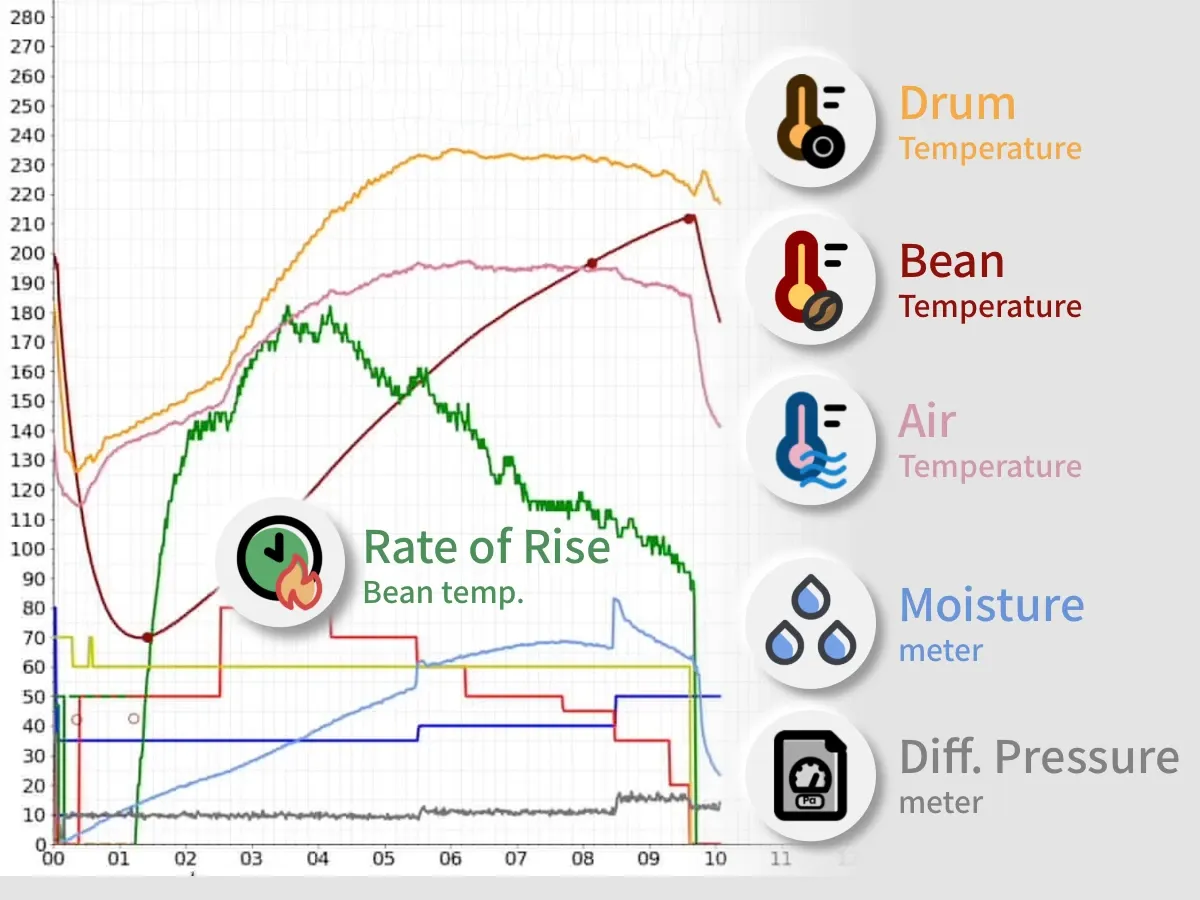

3. Digital Roast Data Collection

Full Knowledge of Your Roasts

Fully digitalized roast control & roast data sensors enable users to roast with precision & insight.

Roast data includes :

Bean temperature

Bean temperature rate of rise (RoR)

Exhaust air temperature

Drum surface temperature

Differential pressure

Exhaust Moisture*

Roast data includes :

Bean temperature

Bean temperature rate of rise (RoR)

Exhaust air temperature

Drum surface temperature

Differential pressure

Exhaust Moisture*

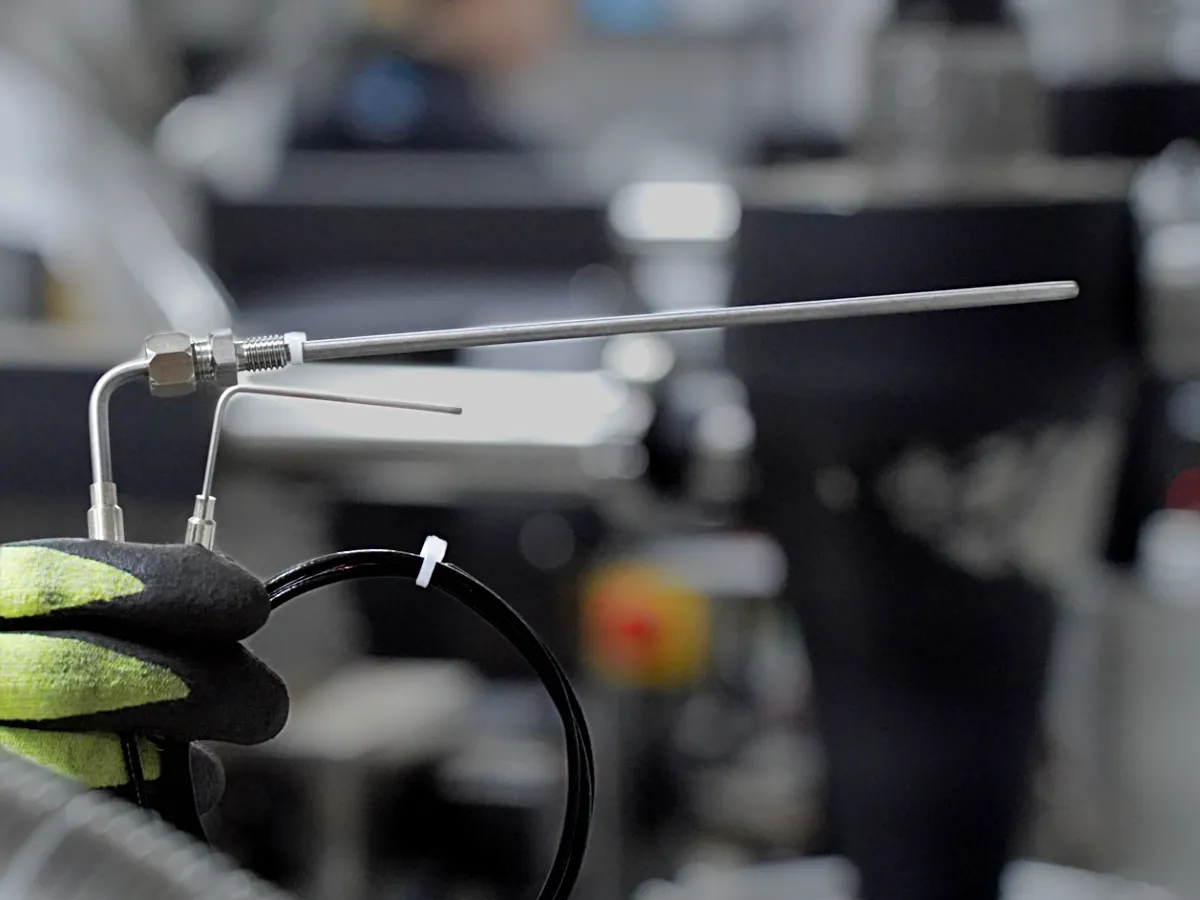

Meticulous in Data Consistency

Low quality data sometimes is worse than no data.

To obtain truly informative insights, we make sure that our roast data collection is flawless from an engineering perspective – starting from making & hand-tuning each & every temperature sensing probe!

To obtain truly informative insights, we make sure that our roast data collection is flawless from an engineering perspective – starting from making & hand-tuning each & every temperature sensing probe!

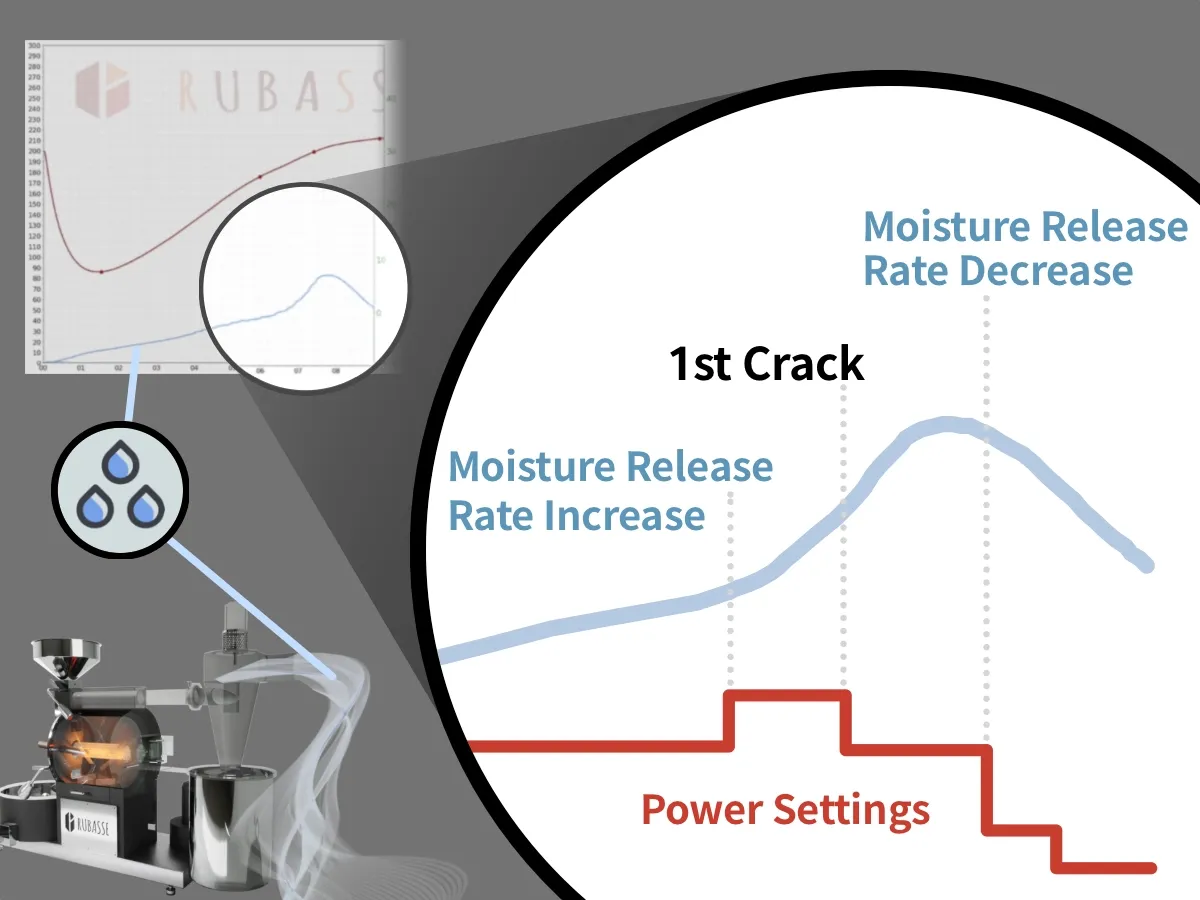

Exhaust Moisture Meter

A New Perspective

“ Actually seeing how the coffee release moisture during roasting really elevates a roaster’s understanding about the roasting process. “

— William Cheng, Founder of Rubasse

1st Crack Navigator

● More reliable way to mark 1st crack

● Perfect post-crack heat application

● Avoid the “Crash & Flick” with ease

The above are some of the highlighted benefits roasters gain after including our exhaust moisture data into their roastings.

● Perfect post-crack heat application

● Avoid the “Crash & Flick” with ease

The above are some of the highlighted benefits roasters gain after including our exhaust moisture data into their roastings.

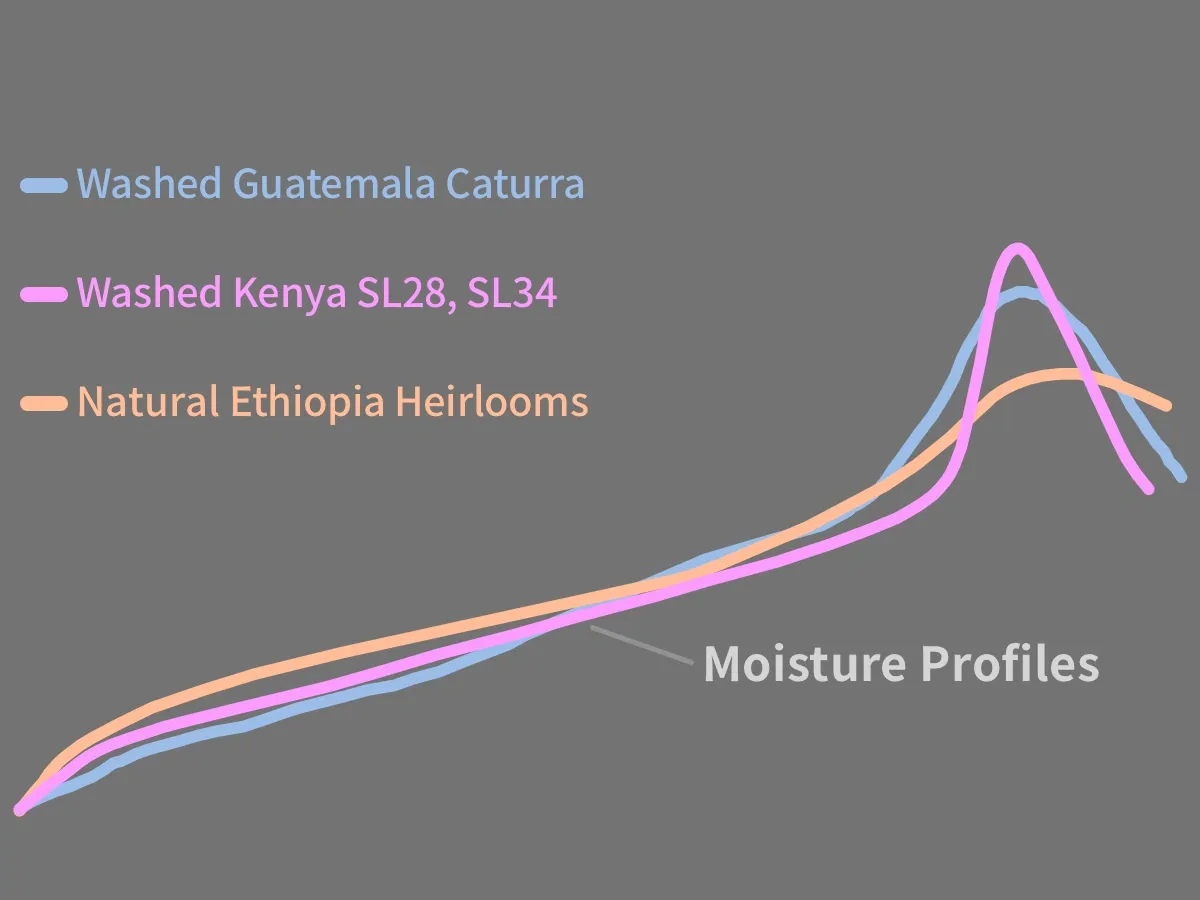

Visualize How Coffees “Roasts Differently

You can now see possible reasons behind common sayings such as “Kenyan coffees like to crash” or “Naturals tend to fly-off near the end of roasting”…etc.

The exhaust moisture curve gives you previously inaccessible, crucial information when designing roasting heat profiles for individual coffees.

The exhaust moisture curve gives you previously inaccessible, crucial information when designing roasting heat profiles for individual coffees.

More About the Exhaust Moisture Meter

Roast It the Way You Like It

Just More Efficiently & Consistently

Micro

Daily production roasting made simple.

● Max. 3kg capacity

● Min. 300g capacity

● 220V single phase power

● Unlimited back-to-back roastings

● 100% automated roast workflow

● Min. 300g capacity

● 220V single phase power

● Unlimited back-to-back roastings

● 100% automated roast workflow

Nano

Small scale roasting powerhouse.

● Max. 600g capacity

● Min. 200g capacity

● 220/110V single phase power

● Unlimited back-to-back roastings

● Min. 200g capacity

● 220/110V single phase power

● Unlimited back-to-back roastings

What Our Users Love

Hassle-Free Setup

Our 220V, 1-phase power makes our roasting machines extremely set-up friendly.

Worry no more about gas pipelines or industrial 3-phase electicity settings.

Worry no more about gas pipelines or industrial 3-phase electicity settings.

Simple Maintenance

If you know how to change a lightbulb, you can do maintenance on a Rubasse roaster.

NIR heat source, airflow system, and our roasting drum are all designed with easy cleaning in mind.

NIR heat source, airflow system, and our roasting drum are all designed with easy cleaning in mind.

Intuitive Roasting

Linear heat energy output calibration and the direct heating enables our users to roast intuitively.

Want more energy applied immediately? Just crank up the power %.

Want more energy applied immediately? Just crank up the power %.

What Our Users Say

I have tried some traditional roasters, but with the Rubasse, I discovered unexplored flavor notes in my Indian coffee beans that I have never found with other roasters. It’s quite surprising how the Rubasse can reveal new notes & aromas.

JC Mysore, Green coffee exporter & coffee roasters, India

The roaster is very responsive with a high level of control allowing you to easily roast your coffee in the way you want, then after you have created your ideal profile you are able to replicate the roast knowing that it will keep repeating your roast with a high level of consistency.

Bay coffee roasters, coffee roastery & cafe, United Kingdom

See the Machines in Action

Get a Quotation

Rubasse Distributors

2025 Global Promo: Up to 20% Off & More!

If you place your order for our roasting machine between 28~30th November, than the Global Promo discount will be applied to your order.

What’s more, if your region has a local Rubasse distributor, you can receive extra gifts! (click on the flags below for details in each region).

United Kingdom

Cambodia

Indonesia

Malaysia

Philippines

Thailand

United Arab Emirates

Hong Kong

If No Distributor in Your Region,

Please just contact us through the form below.

No matter when you contacted us, as long as your order is placed between 28~30th November, the 20% discount still applies!