Fully-Electric, Table-top Coffee Roasting Powerhouse

The Hyper 1.2kg – Lightweight, Fully-Digital & Automatic Coffee Roaster

The Hyper 1.2kg is tailored for precise & exquisite small batch roasting,

while still having the ability to absolutely churn out incredible roasts batch after batch consistently and fully-automatically.

while still having the ability to absolutely churn out incredible roasts batch after batch consistently and fully-automatically.

Revolutionary Near Infrared Radiation Roasting Tech

By utilizing radiation as the main heat transfer method,

our patented Near Infrared (NIR) central heat source located at the center of the roasting chamber gives roasters the ultimate direct control over the energy applied onto the coffee anytime during a roast.

This allows roasters to have ultra-responsive roast heat control and effortlessly roast batches ranging from 300g up to 1.2kg.

our patented Near Infrared (NIR) central heat source located at the center of the roasting chamber gives roasters the ultimate direct control over the energy applied onto the coffee anytime during a roast.

This allows roasters to have ultra-responsive roast heat control and effortlessly roast batches ranging from 300g up to 1.2kg.

A Small & Compact 1kg Coffee Roaster

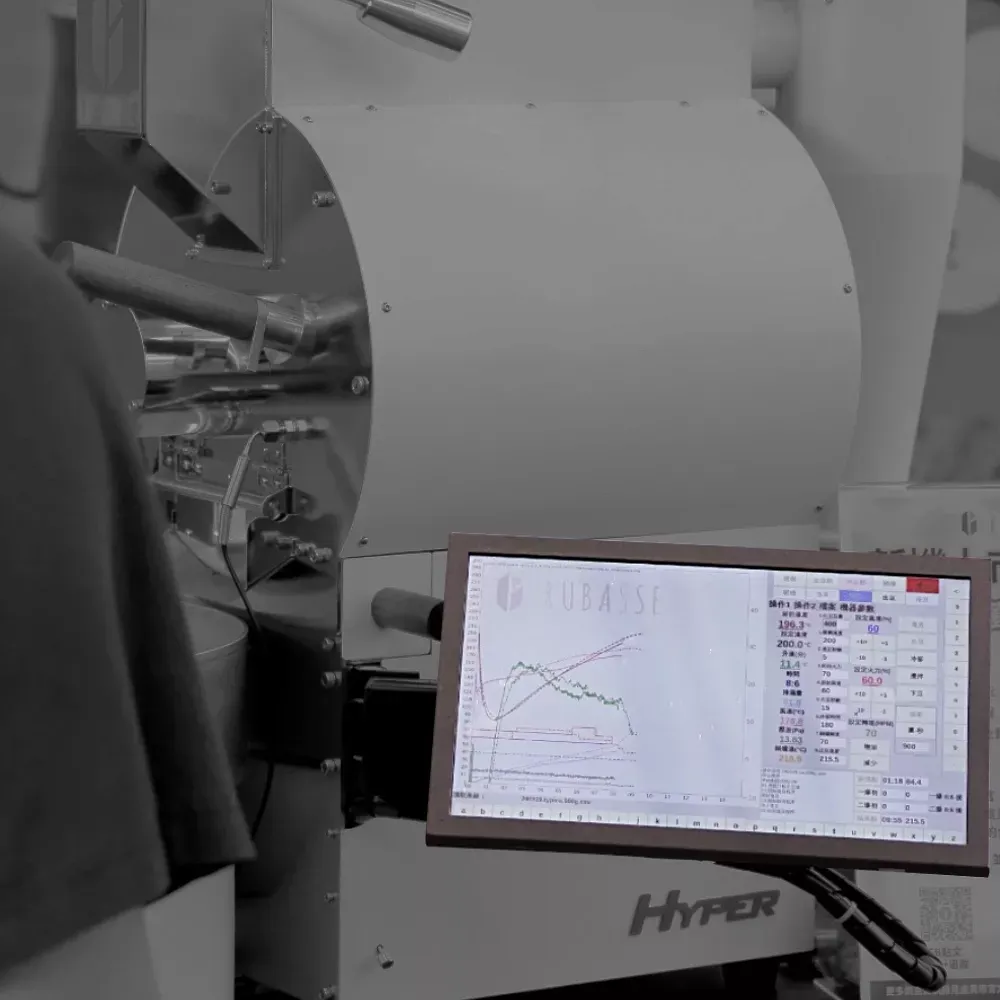

With Hyper’s unique “multi-directional extension touch screen”,

users can set up & operate the Hyper 1.2kg with tons of flexibility.

Combined this with the compact footprint of the Hyper 1.2kg,

Even irregular or tight spaces can be transformed into your personal coffee roasting sanctuary.

users can set up & operate the Hyper 1.2kg with tons of flexibility.

Combined this with the compact footprint of the Hyper 1.2kg,

Even irregular or tight spaces can be transformed into your personal coffee roasting sanctuary.

Effortless Roasting, Optimal Results

Stable, precise, and fully digitalized roast controls combined with our direct Near-Infrared heat source enable users to bring out the best of each coffee, shorten the coffee roasting learning curve, & quickly build insightful experiences that leads to expertise.

A “Flavor Guarantee”: Near-Infrared Radiation Roasting

The direct and penetrating heating properties of our NIR (Near-Infrared) technology ensure that every batch is truly “roasted” rather than “baked”.

NIR roasting fully unlocks the flavor characteristics of each coffee bean & make controlling each coffee’s flavor development straight-forward & precise.

NIR roasting fully unlocks the flavor characteristics of each coffee bean & make controlling each coffee’s flavor development straight-forward & precise.

Fully Digital Roast Controls: Intuitive and Precise

Airflow, heating energy, and drum speed are all precisely controlled via the touch panel on the Hyper 1.2kg.

By digitalizing all roast controls, we strive to offer a roasting machine with ultimate precision in controlling the roast and ease of operating.

By digitalizing all roast controls, we strive to offer a roasting machine with ultimate precision in controlling the roast and ease of operating.

The Perfect Match for Small-Scale Production

Precise roast profile replication system plus our fully-automated roasting workflow help users optimize the efficiency of the 1.2kg roaster.

Fully Automated Roasting System for Effortless Operation

From charging the green coffee to dropping the roasted beans and cooling,

everything can be effortlessly managed with just a touch of the screen.

everything can be effortlessly managed with just a touch of the screen.

Precise Roast Profile Replication

Equipped with Rubasse’s “Lv.3 Auto-pilot Profile Replication” system,

the Hyper 1.2kg replicates your original roast profile using precise algorithm-driven heat compensation while respecting your original heat application design.

With just the press of a button, roasters can consistently recreate the perfect flavor in the most time- and energy-efficient way.

the Hyper 1.2kg replicates your original roast profile using precise algorithm-driven heat compensation while respecting your original heat application design.

With just the press of a button, roasters can consistently recreate the perfect flavor in the most time- and energy-efficient way.

One Touch, Smart Replication

With Hyper’s fully automated roast system, coffee business owners/operators who juggle multiple tasks no longer need to stay glued to the roasting machine.

Requiring just under 1 minute of total labor time per batch, the Hyper 1.2kg maximizes the efficiency of a small batch roasting machine in terms of time & labor while maintaining a high level of production quality.

Requiring just under 1 minute of total labor time per batch, the Hyper 1.2kg maximizes the efficiency of a small batch roasting machine in terms of time & labor while maintaining a high level of production quality.

Precise Measurements, Profound Insights

The quality of each roast data measurement is a non-negotiable commitment at Rubasse; This ensures that accurate and stable roasting data becomes a reliable reference point and learning source during each and every roasting process.

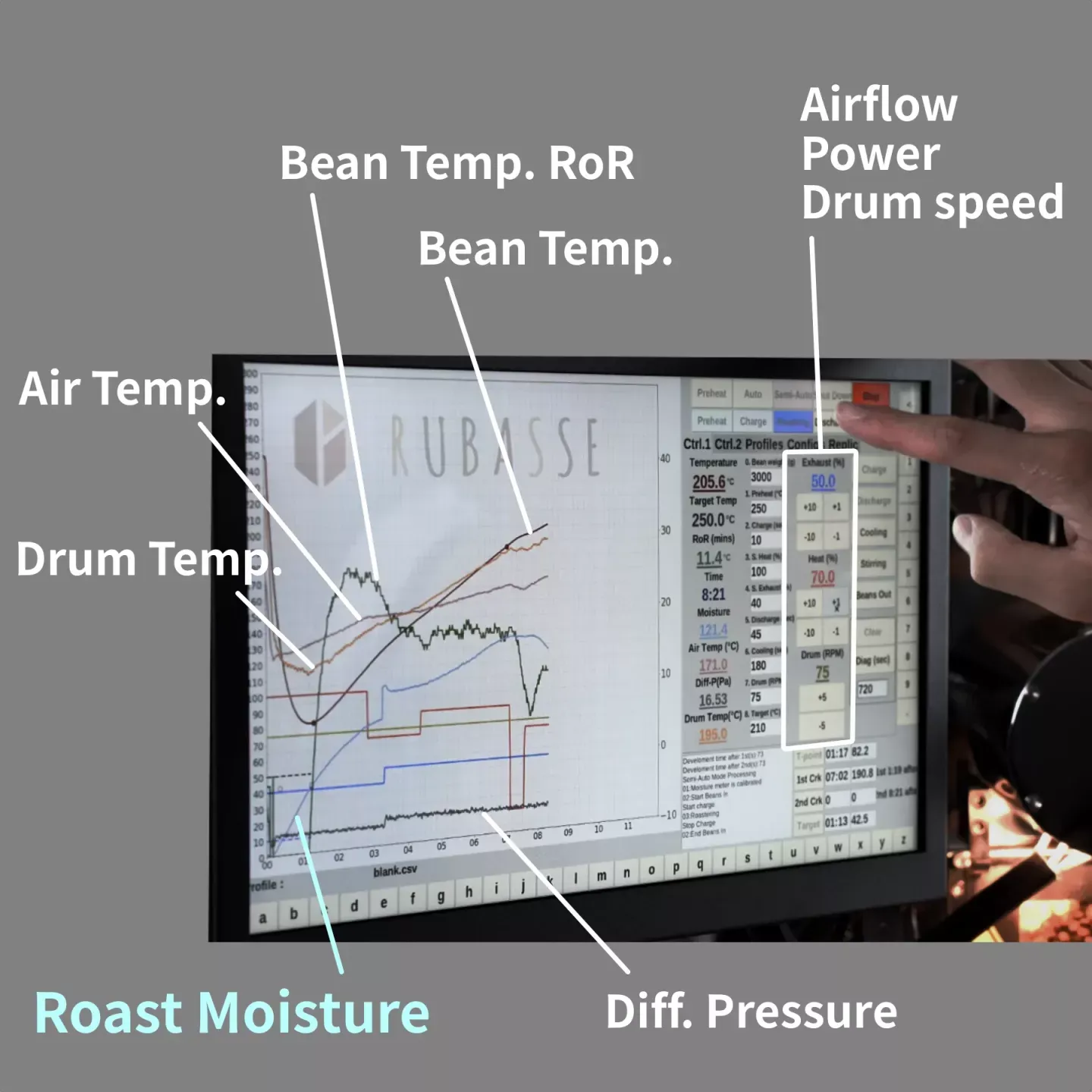

Comprehensive Data for Real-Time Roast Monitoring

Through the panel, you can monitor data such as Bean temperature, Bean temperature RoR (rate of rise), Air temperature, Drum temperature, Differential Pressure, and Roast Moisture Release.

This not only serves as a reference for adjusting and improving roast operations but also helps roasters accumulate knowledge and summarize insights

This not only serves as a reference for adjusting and improving roast operations but also helps roasters accumulate knowledge and summarize insights

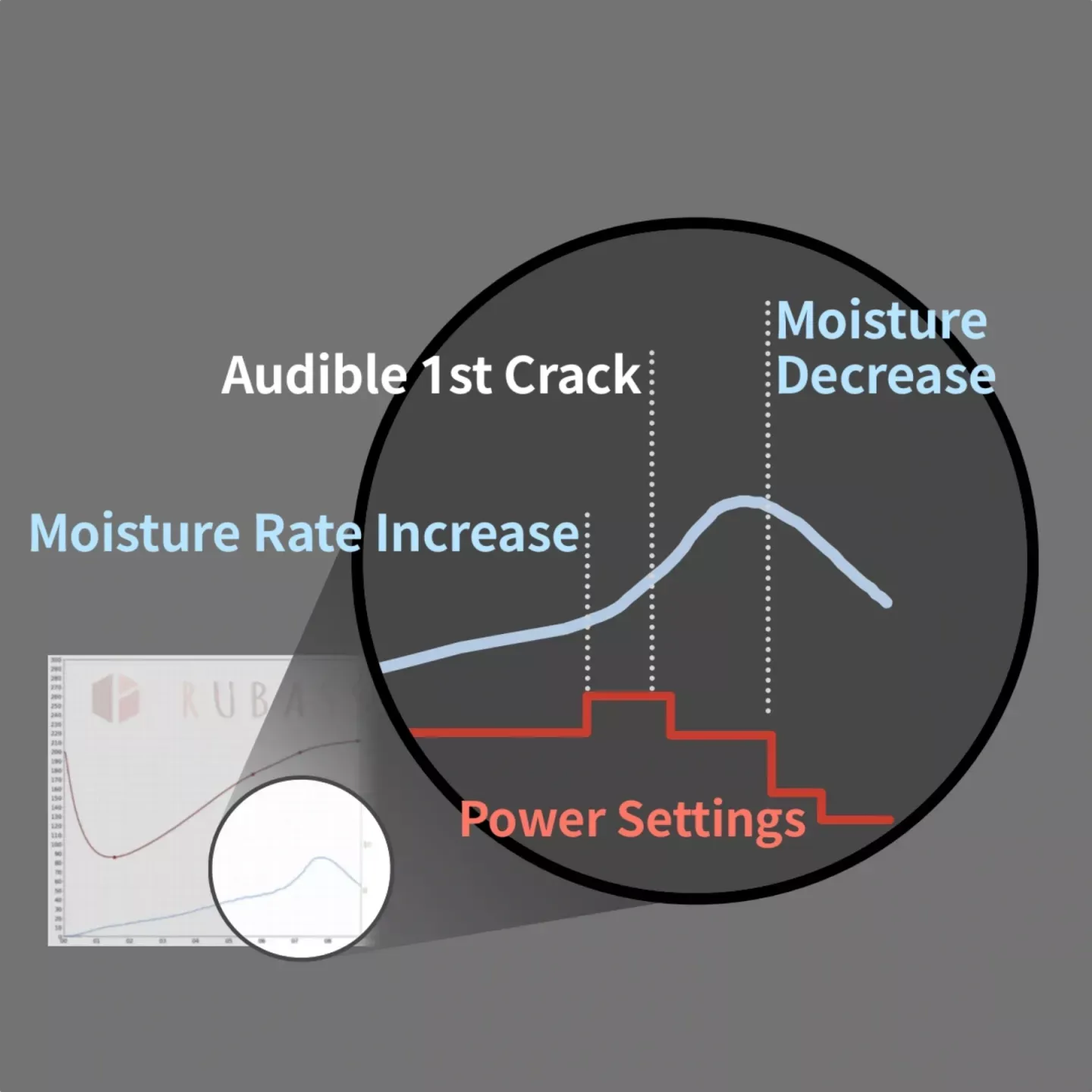

Roast Moisture Profiling: A Global First

Roasting is essentially the process of “gradual dehydration” of green coffee beans.

Introducing our Exhaust Moisture Meter, Rubasse aims to provide roasters with a new perspective on the entire roasting process.

During actual roasting, data from the Exhaust Moisture Meter can aid:

● Roast level determination

● Heat adjustment during the development phase

● Timing the perfect batch dropping moment

Introducing our Exhaust Moisture Meter, Rubasse aims to provide roasters with a new perspective on the entire roasting process.

During actual roasting, data from the Exhaust Moisture Meter can aid:

● Roast level determination

● Heat adjustment during the development phase

● Timing the perfect batch dropping moment

Specifications

To Ask More or Get a Quotation

We will be in touch with you shortly.

Whether you want to schedule a live roast demo or simply just ask more details about how the machine works, we are always glad to be answering your questions!

Whether you want to schedule a live roast demo or simply just ask more details about how the machine works, we are always glad to be answering your questions!