Fully Automated Professional Roasting Solution

The Most Efficiency Way of Specialty Coffee Roasting

The Micro 3kg roaster carries Rubasse’s patented near-infrared heating that has high heating efficiency and low energy consumption, while our profile replication system automatically controls roasting heat, airflow, and drum speed in order to replicate your desired roast with perfect precision batch after batch.

Fully automated roasting mechanism not only simplifies the roasting operation process, but also allows the profiling system to automatically control the charge, discharge, and cooling of the beans. This, together with the auto profile replication system, ensures that the Rubasse Micro 3kg can take care of everything on the roasting side of your coffee business for you.

Fully automated roasting mechanism not only simplifies the roasting operation process, but also allows the profiling system to automatically control the charge, discharge, and cooling of the beans. This, together with the auto profile replication system, ensures that the Rubasse Micro 3kg can take care of everything on the roasting side of your coffee business for you.

Introducing You To

Near-Infrared Radiation Roasting

Ultra-precise & direct roast control, 50% less energy usage, and easy flavor development — Near Infrared Radiation makes them all possible.

The use of radiation redesigns roasting in a truly innovative fashion.

The use of radiation redesigns roasting in a truly innovative fashion.

Center-placed Heat Source :

Direct Heat Application

By utilizing radiation as the main heat transfer method AND putting the radiant heat source inside the drum and right at the center of the roast chamber, we bypassed much of the complex heat transfer pathways in traditional roasting systems and increased both the heat control responsiveness and heat transfer efficiency of coffee roasting.

Ultra-Precise & Responsive

Roasting Heat Control

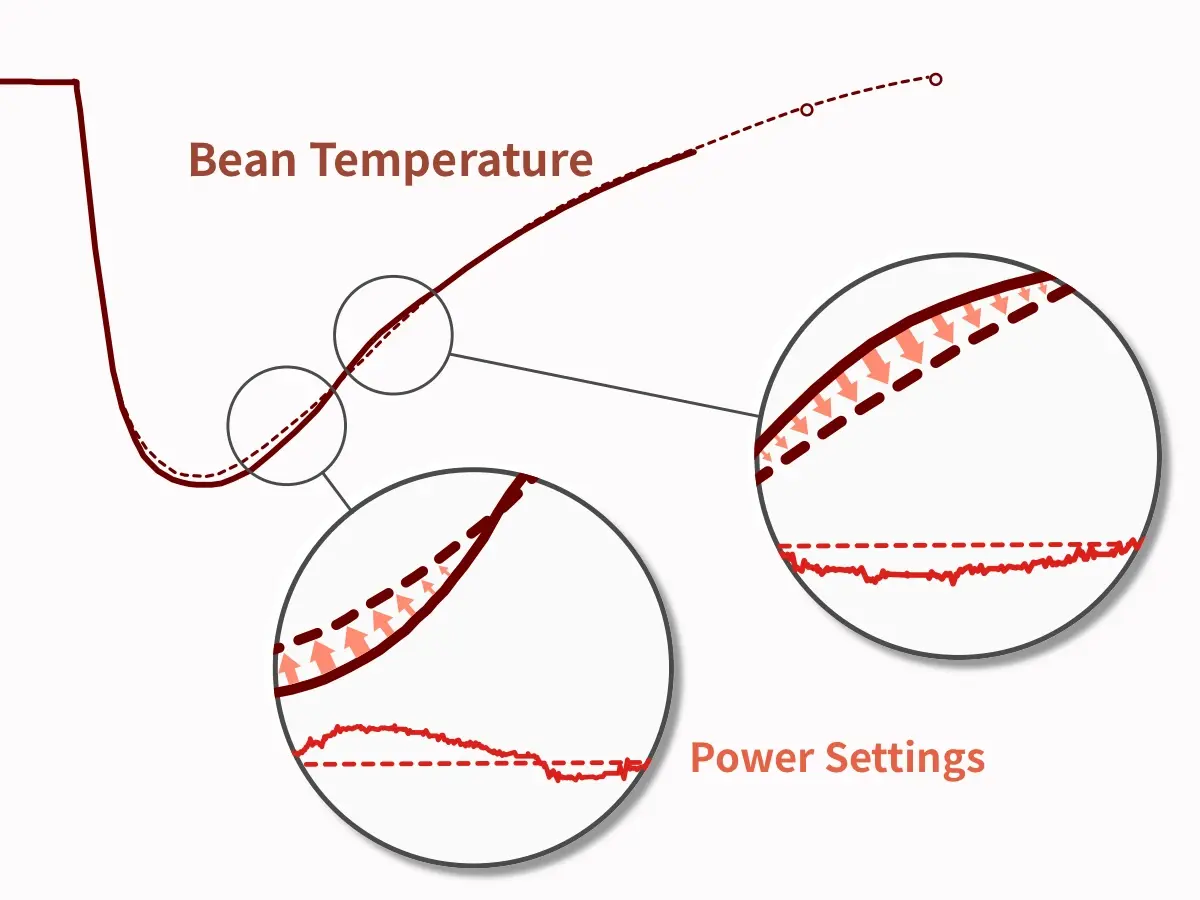

Thanks to our patented Near Infrared (NIR) central heat source, our machine can give roasters responsive & direct control over the energy applied onto the coffee anytime during a roast – with just a simple touch on our screen!

Also, the roast heat settings can be altered in precise and linear 1% increments, providing users the ability to micro-adjust their roasts in search for “the perfect cup”.

Also, the roast heat settings can be altered in precise and linear 1% increments, providing users the ability to micro-adjust their roasts in search for “the perfect cup”.

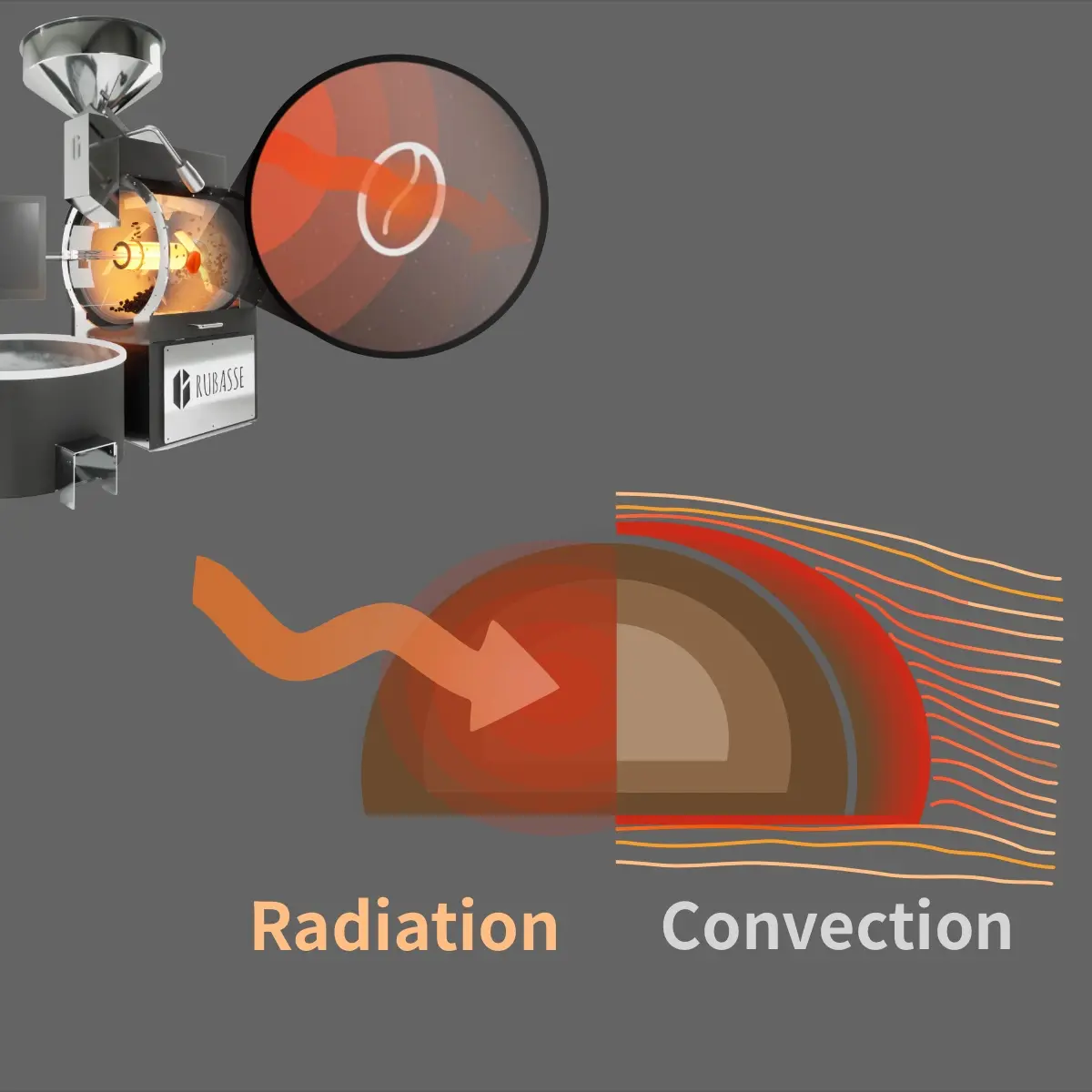

Radiation ≫ Convection :

Efficient & Even Heating

When applied, radiant heat is evenly absorbed by the total mass of a coffee bean.

In contrast, convective heat (hot air) is mainly & firstly absorbed by the outer surface of a coffee bean, and the heat will need time to penetrate deeper.

Roasting with radiation means:

● Faster roast development (especially as the beans get darker)

● Less uneven and/or prolonged “baked” roasts.

In contrast, convective heat (hot air) is mainly & firstly absorbed by the outer surface of a coffee bean, and the heat will need time to penetrate deeper.

Roasting with radiation means:

● Faster roast development (especially as the beans get darker)

● Less uneven and/or prolonged “baked” roasts.

The Perfect Production Partner

Being our current flagship model, the Micro 3kg is a professional and fully-automated roasting solution designed to express the best a coffee has to offer while handling large-scale, back-to-back routine roasts with ease.

Fully Automated Roasting System for

Effortless & Streamlined Workflow

From preheating & charging the green coffee to dropping the roasted beans and cooling,

everything can be effortlessly managed with just a touch of the screen.

With the possibility to automate the chore-like routine roasts, Rubasse roasters give busy small cafe owners back their precious time and let roasters focus on the truly important tasks that grow their businesses.

everything can be effortlessly managed with just a touch of the screen.

With the possibility to automate the chore-like routine roasts, Rubasse roasters give busy small cafe owners back their precious time and let roasters focus on the truly important tasks that grow their businesses.

Fully Automated Roasting (1) Auto Preheating

The “Auto-Pilot” system has an Auto Preheat function that automatically idles the bean temperature at your designated temperature.

Power output and airflow setting are controlled by the system to ensure stable initial energy at the start of the roast.

Power output and airflow setting are controlled by the system to ensure stable initial energy at the start of the roast.

Fully Automated Roasting (2)

Our Back-tracking Algorithm

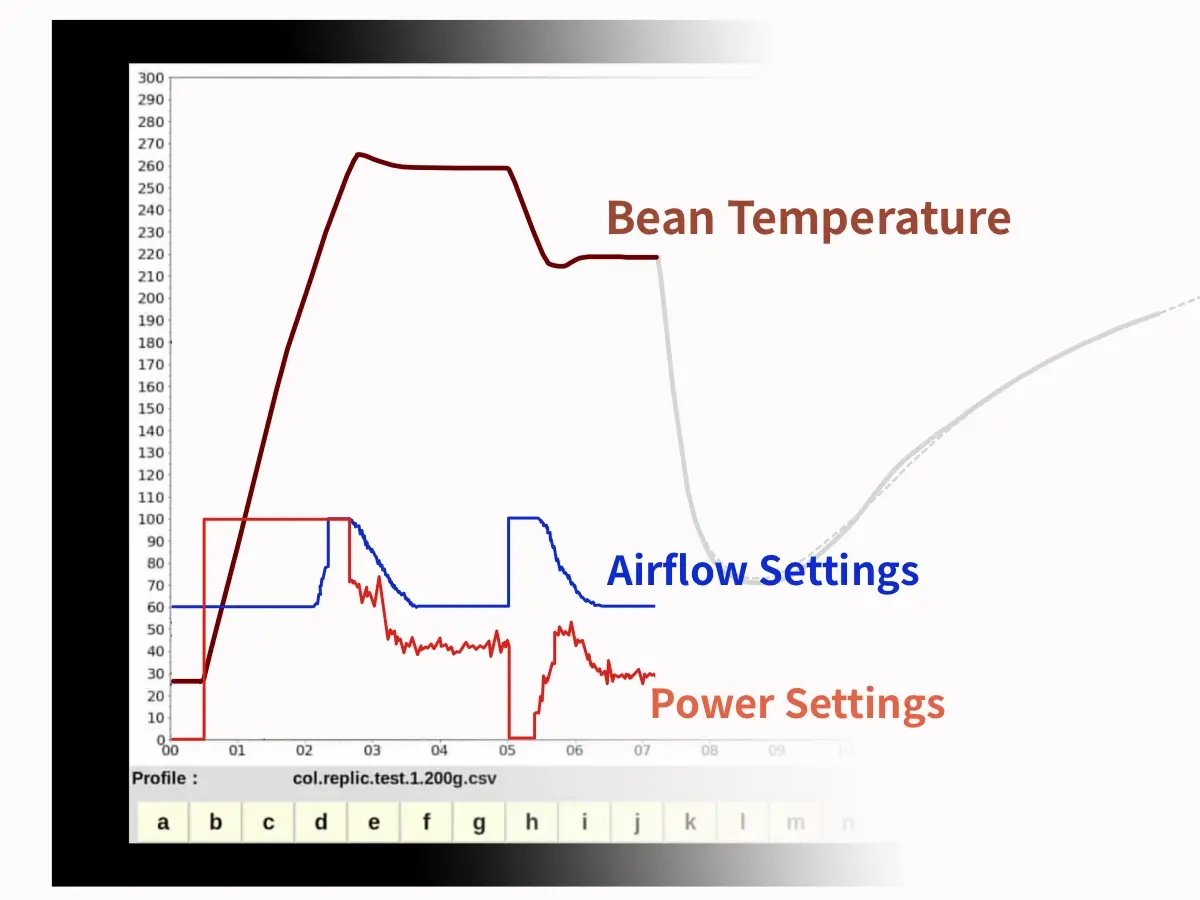

Specialized algorithm takes full control over radiation heat & airflow settings, corrects temperature deviations swiftly, and replicates your unique profile with precision both on the graph & in the cup.

Fully Automated Roasting (3)

Differential Pressure Profiling

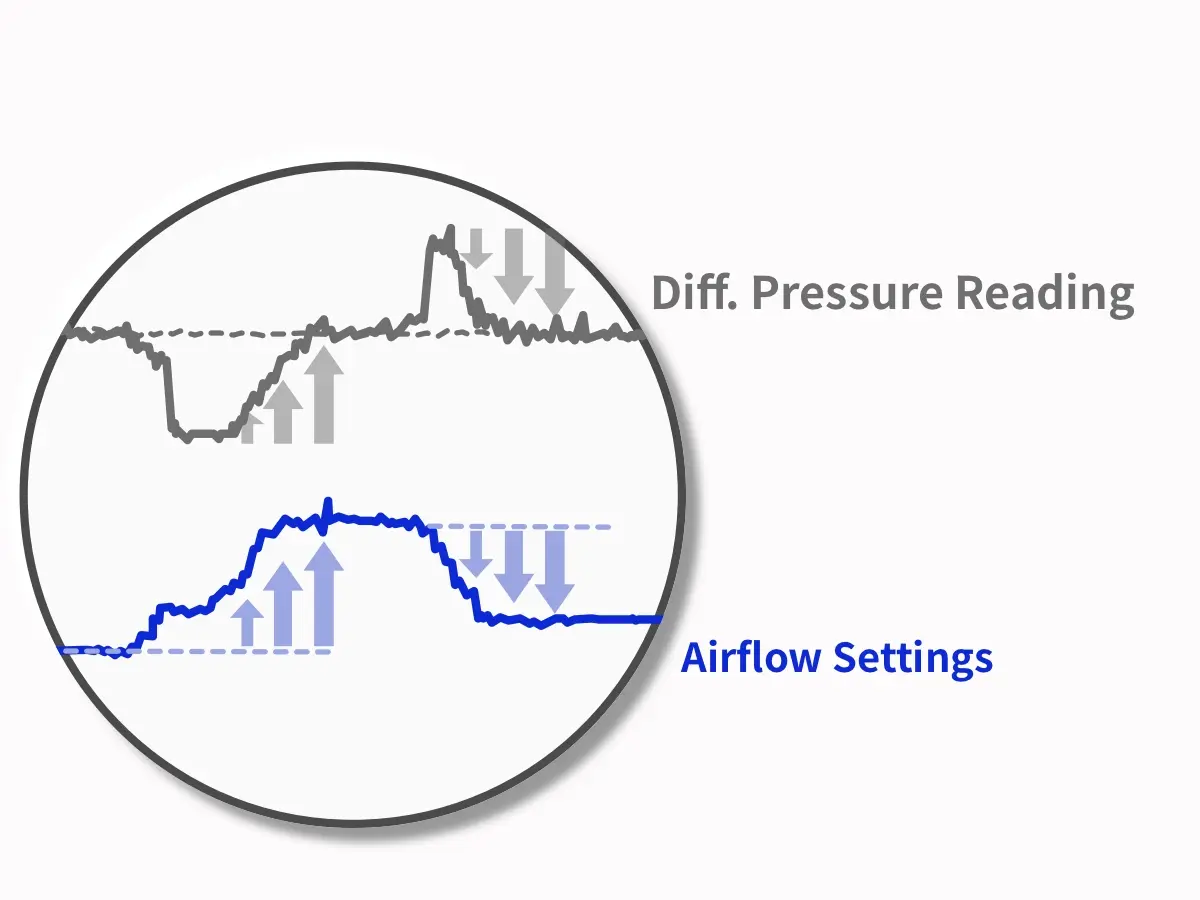

Rubasse’s “Pressure Compensation” feature mitigates possible effects on the roast caused by air pressure issues such as clogged ducts over time or weather/ambient changes…etc.

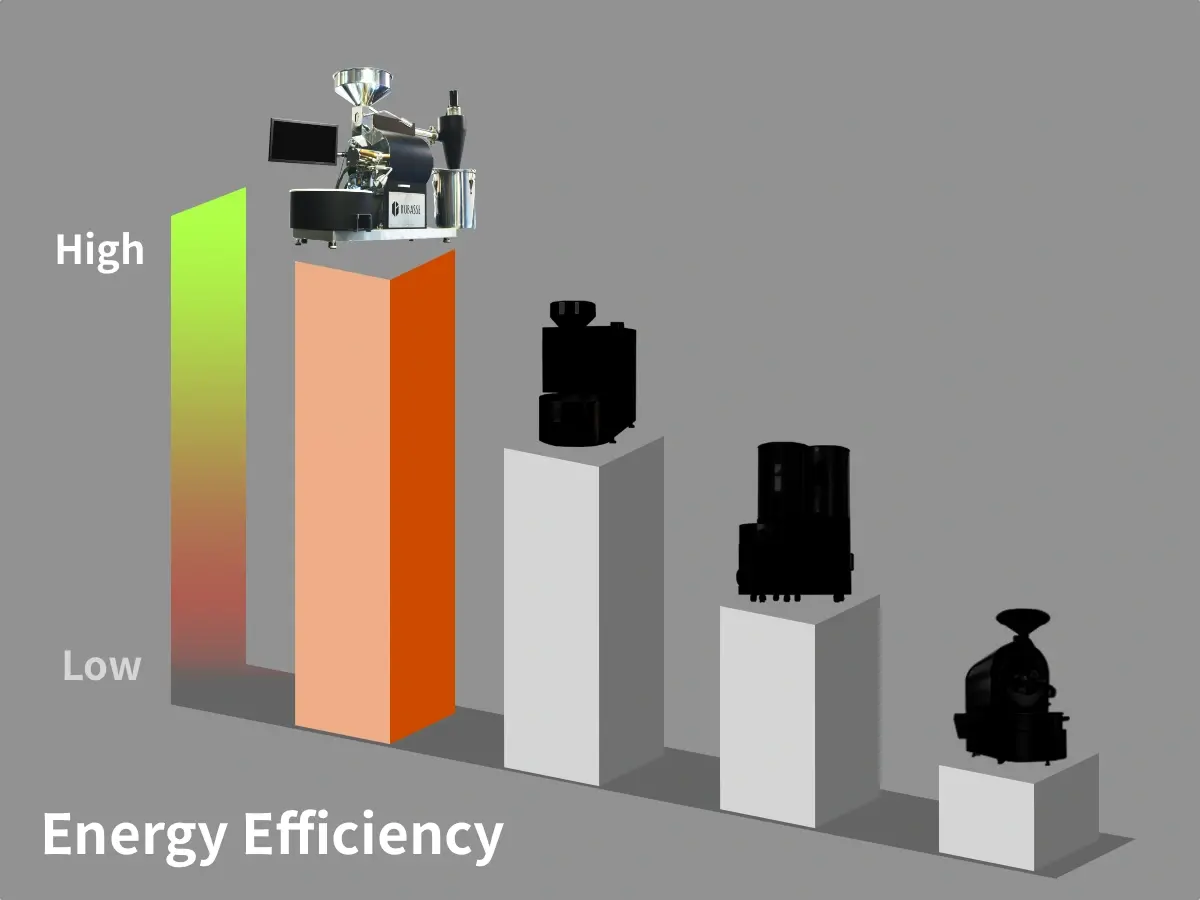

NIR Roasting“…results in approximately 50% less energy consumption due to the effective heat method.”

As researchers find out and noted in the EECA Technology Scan report (page 12), Switching the primary roasting energy source from hot air to radiation benefits roasters with tremendous energy savings.

More Than 50%

Roast Energy Savings

Switching the primary roasting energy source from hot air to radiation benefits roasters with tremendous energy savings.

Our center-placed radiation power element ensured maximum radiant heat utilization, resulting in the world’s most energy efficient roasting process (proven by the 3rd party research linked here).

Our center-placed radiation power element ensured maximum radiant heat utilization, resulting in the world’s most energy efficient roasting process (proven by the 3rd party research linked here).

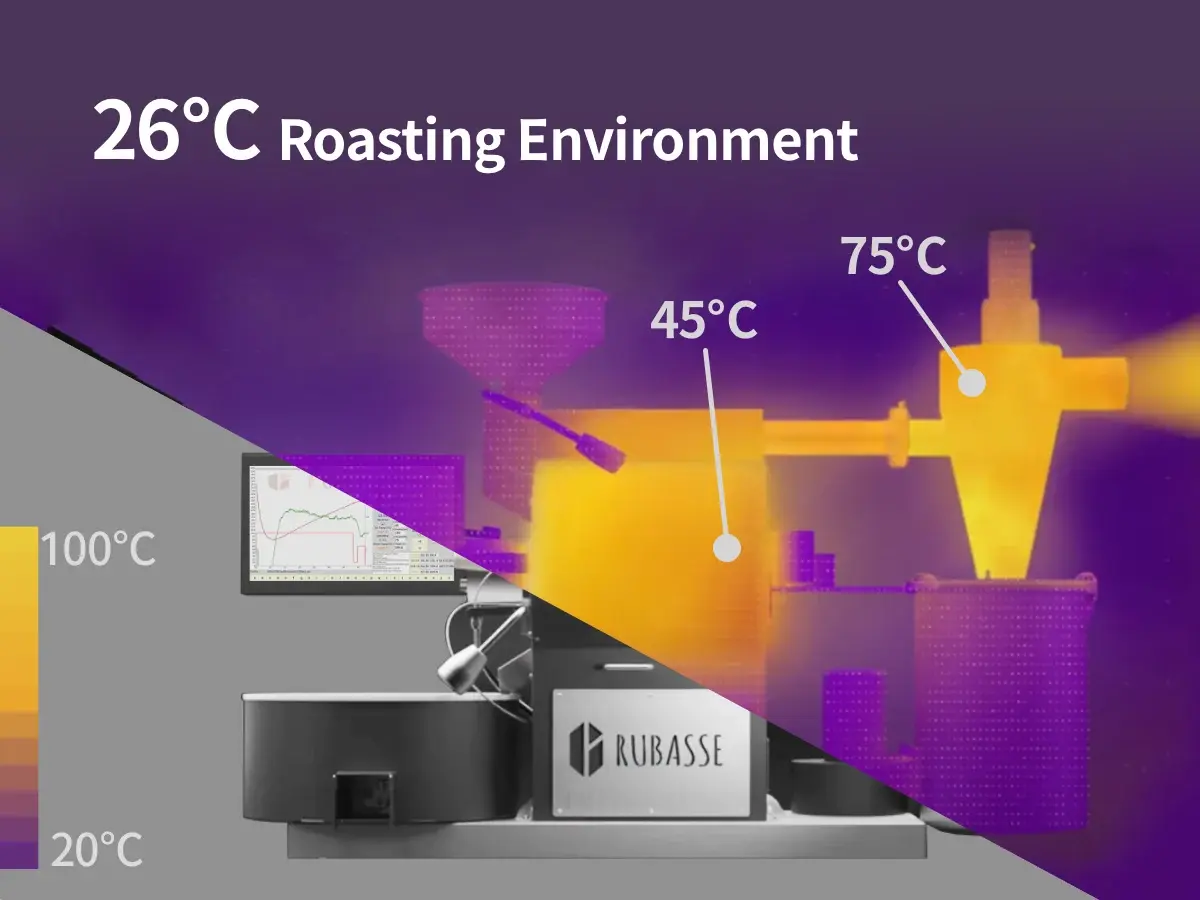

Efficient Roast Energy Usage =

Cool & Comfortable Roasting Environment

Improving roast energy efficiency by roasting with radiation also means less waste heat being released in to the roasting environment.

The benefits:

● Comfortable, cool roasting sessions

● Way less money spent on air conditioning

The benefits:

● Comfortable, cool roasting sessions

● Way less money spent on air conditioning

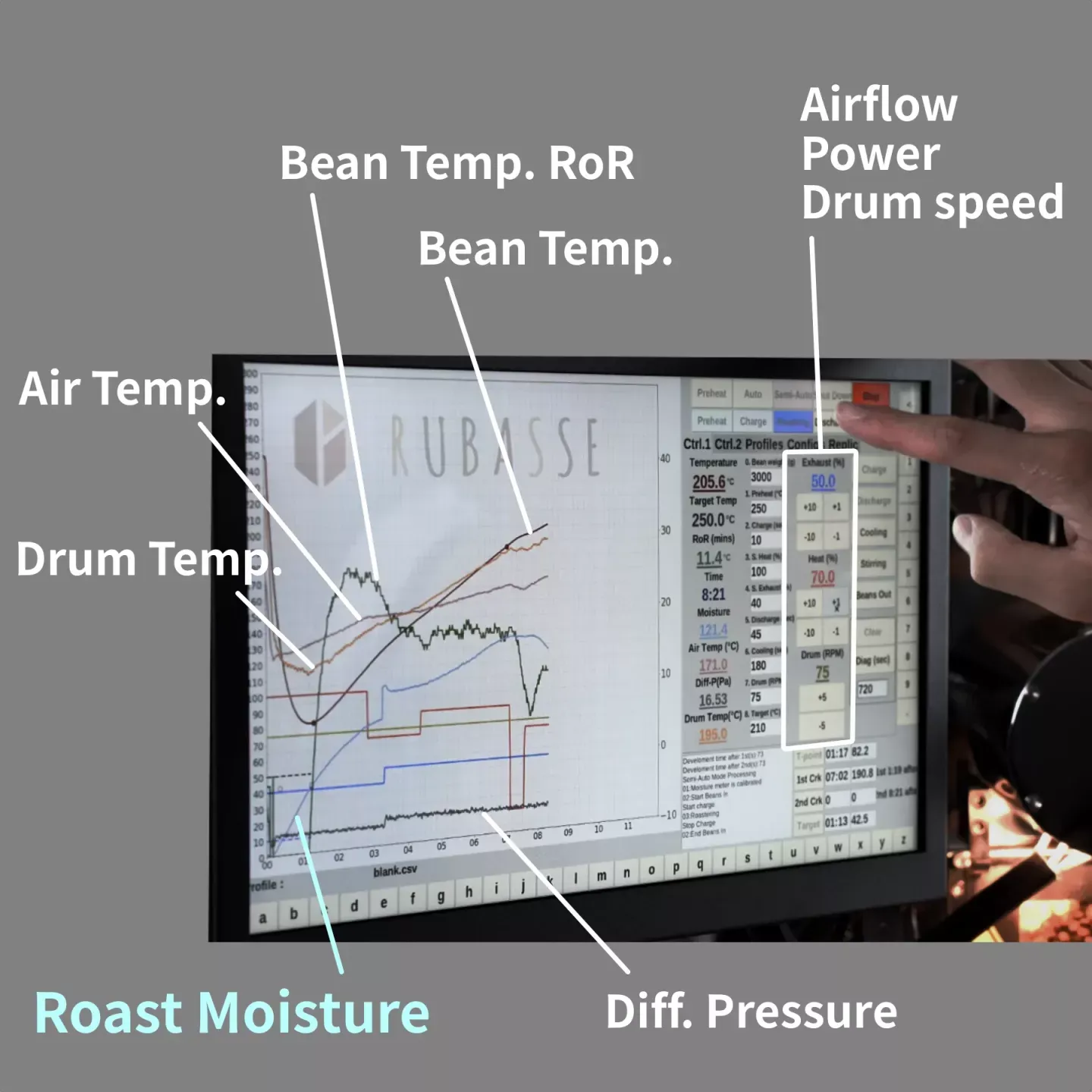

Precise Measurements, Profound Insights

The quality of each roast data measurement is a non-negotiable commitment at Rubasse;

This ensures that accurate and stable roasting data becomes a reliable reference point and learning source during each and every roasting process.

This ensures that accurate and stable roasting data becomes a reliable reference point and learning source during each and every roasting process.

Comprehensive Data,

Fully Digital Roast Controls

Through the panel, you can monitor data such as Bean temperature, Bean temperature RoR (rate of rise), Air temperature, Drum temperature, Differential Pressure, and Roast Moisture Release.

Also, Airflow, heating energy, and drum speed are all precisely controlled via the touch panel, offering ultimate precision in controlling the roast while keeping the adjustments easy and intuitive.

Also, Airflow, heating energy, and drum speed are all precisely controlled via the touch panel, offering ultimate precision in controlling the roast while keeping the adjustments easy and intuitive.

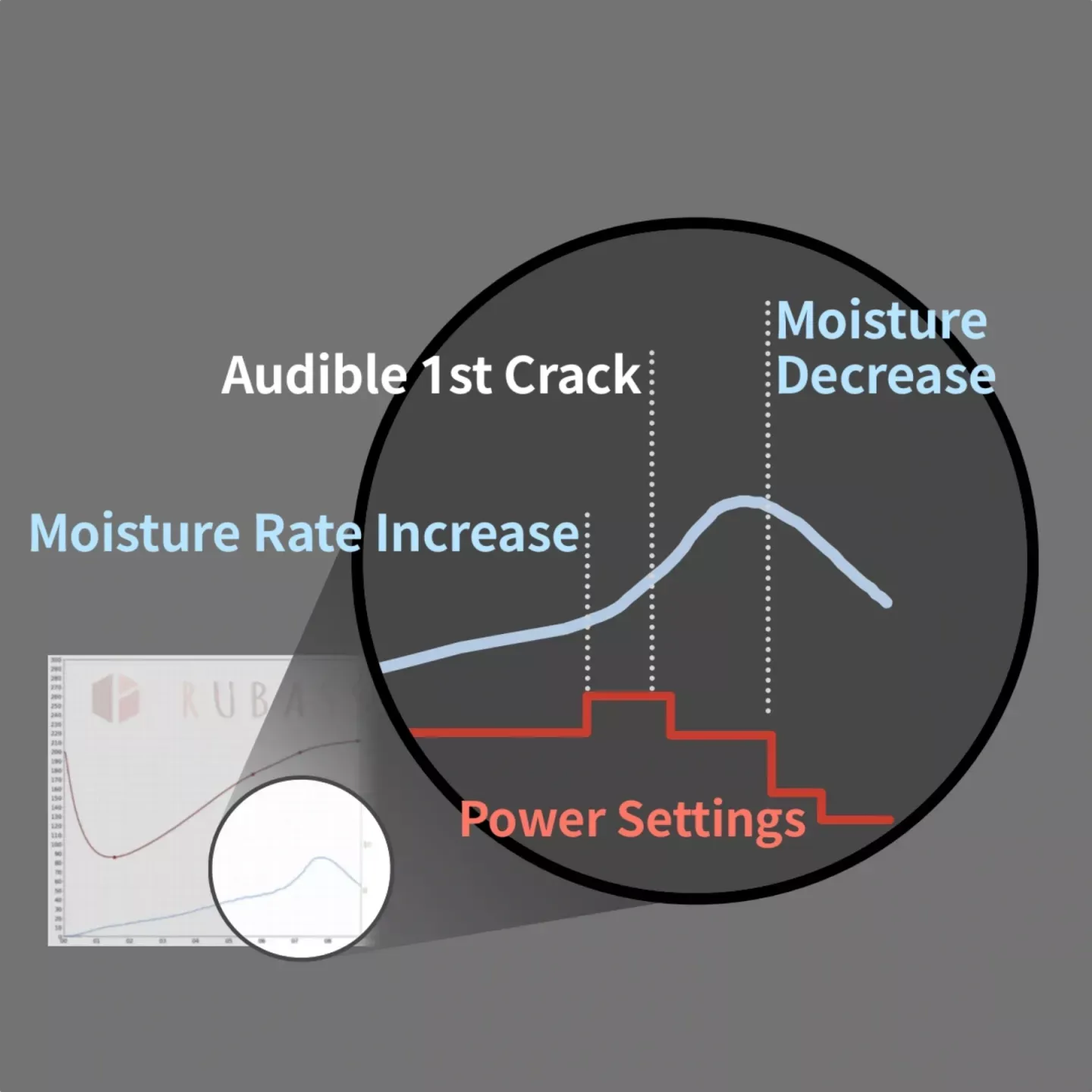

Live Roast Moisture Profile:

Visualize Roast Development Like Never Before

Roasting is essentially the process of “gradual dehydration” of green coffee beans.

Introducing our Exhaust Moisture Meter, Rubasse aims to provide roasters with a new perspective on the entire roasting process.

During actual roasting, data from the Exhaust Moisture Meter can aid:

● Roast level determination

● Heat adjustment during the development phase

● Timing the perfect batch dropping moment

Introducing our Exhaust Moisture Meter, Rubasse aims to provide roasters with a new perspective on the entire roasting process.

During actual roasting, data from the Exhaust Moisture Meter can aid:

● Roast level determination

● Heat adjustment during the development phase

● Timing the perfect batch dropping moment

Specifications

To Ask More or Get a Quotation

We will be in touch with you shortly.

Whether you want to schedule a live roast demo or simply just ask more details about how the machine works, we are always glad to be answering your questions!

Whether you want to schedule a live roast demo or simply just ask more details about how the machine works, we are always glad to be answering your questions!